American Farriers Journal

American Farriers Journal is the “hands-on” magazine for professional farriers, equine veterinarians and horse care product and service buyers.

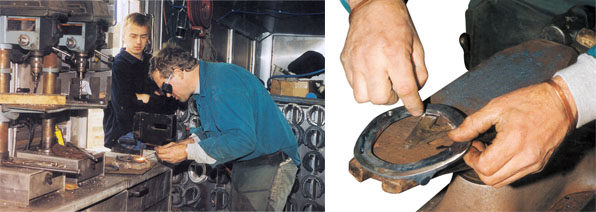

ADDING SUPPORT. Carl Hayden checks the fit on a bar insert, above, right, before welding it to an egg bar shoe as apprentice Sean Matousek looks on. Hayden uses bar shoes extensively in his practice, which consists primarily of hunter-jumpers.

FARRIER CARL HAYDEN lives a few hundred yards down a winding road from the picture-postcard New Hampshire village of Kensington, just a stone’s throw from the Massachusetts’s border. When I arrive at his home on a recent spring morning, he’s doing what a lot of farriers do in those precious few morning minutes before embarking on a hard day’s work.

He’s shoeing a horse — his own big blonde Belgian draft horse named Major.

8 a.m. Major has already been led into stocks by the time I arrive and Hayden and his apprentice, Sean Matousek, have prepped the horse’s front feet and Hayden is nailing a shoe in place. He tells me he’s preparing this horse and its partner for the coming season of pulling competitions.

“This is something I’m getting back into,” Hayden says. “I used to have a team that I competed with, but I’ve been out of it a few years. I bought this team just a little while ago.”

8:11 a.m. Major doesn’t seem to mind the stocks, nor having his feet tied up while they’re worked on. The shoes Hayden is nailing into place have a broad toe calk, as well as lengthy heel calks. Hayden says the draft horses have been barefoot for 18…