With little more than a hammer, anvil and metal tongs that have been the tools of the trade for thousands of years, modern-day farriers demonstrated their craft recently for senior students at Assumption College School in Brantford, Ontario.

At a time when they are considering their careers, Mark Sitko, the school’s manufacturing technology teacher, doesn’t want them to bypass the trades, even the more obscure ones like shoeing horses.

“I don’t know of any parents telling their kids, ‘When you grow up you’ve got to be a farrier,’” says Brian Hyodo, one of three farriers who spent the day at Assumption.

“But in this job there is an enormous sense of satisfaction. It looks simple but there is a ton of training and education behind it,” says Hyodo, treasurer of the Ontario Farriers Association.

It wasn’t that long ago that 26-year-old Andrew Devisser, a farrier from Ayr, was a high school graduate considering his work options.

“When I was looking for a career I had a really rough time. I looked at hundreds of careers. There are so many kids who just take a stab in the dark. I don’t think people turn over enough stones.”

Devisser worked on a horse farm when he was about 12 and liked the idea of blacksmithing. When a close friend became a farrier, Devisser became his assistant. Then, with few options in Canada for training, he went to Nebraska for 8 weeks of training to prepare him for an apprenticeship that lasted about 7 years.

At 37, Kristian Rathlou has spent almost half his life as a farrier to a variety of clients, including owners of show and pleasure horses.

The job is highly physical, but Rathlou, who runs Vulcan Farrier Service in Brantford, says that he likes working with his hands and being outdoors.

“There is a bit of romance to being a blacksmith,” he says. “I now have an anvil that is half steel and half aluminum so it’s half the weight. And technology has changed with the understanding of biomechanics and anatomy. But it’s still taking a foot, shaping a shoe and nailing it on.”

Despite the advancements, Devisser says there’s “no machine that can take the place of a farrier.”

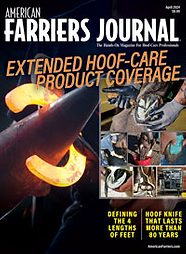

While many of today’s farriers modify pre-fabricated horseshoes, Devisser creates his from scratch, heating a bar of steel in a forge at about 2,200 Fahrenheit and hammering it into shape.

Pounding the glowing metal into a curving horseshoe, Devisser demonstrated for students the strength needed for the job.

It’s not for everyone, he acknowledges.

“Only a fraction who try it end up doing it.”

But Rathlou says that “convincing these kids to become farriers” wasn’t the objective of the day. Instead, he says he wanted to “bring awareness to the wide variety of trades out there.”

Post a comment

Report Abusive Comment