Angie Reynolds hands a shoe for hot fitting to her husband, Peter, at a barn in the Alpharetta, Ga., area. The Reynolds each run a separate farrier business and have their own way of doing things.

The first stop of the day for Angie Reynolds doesn’t actually involve shoeing. It’s just a short distance from her rural home near White, Ga. She pulls her truck to the side of the road and her three children — Matthew, 11, Andrew, 8, and Katrina, 6 — pile out at their school bus stop. Angie waits a few minutes until the bus arrives and she sees the kids safely away. Then she’s ready to start her “Shoeing For A Living” day.

7:10 a.m. Angie makes a quick stop to fill her truck’s diesel fuel tank, then heads out for her first barn call. It’s several miles away and she expects it to only involve some trimming, so she’s left her shoeing trailer behind and loaded the tools she expects to need in the truck. Her route after this stop will take her back by the house and she’ll stop and hook up the trailer then.

Angie Reynolds has been shoeing for 4 years. Even in a profession known for unusual beginnings, hers stands out. Her own shoeing career — as well as that of her husband, Peter — has roots in a mutual interest in polo.

It might not make a great County and Western song, but apparently mothers shouldn’t let their babies grow up to play polo — they might wind up as farriers instead.

Neither Reynolds set out with horseshoeing in mind. Peter came to the United States from his native England with a passion for polo. He played the game and also raised and trained polo ponies to sell. There was a growing interest in the sport in this area northeast of Atlanta, and he was successful enough that he needed to hire exercise riders and grooms and one of them was Angie.

Obviously, the relationship moved beyond that of employer and employee at some point. And at another point, Peter started providing some hoof care for his own ponies, as his horses’ needs outstripped the ability of his farrier to keep up.

Angie adjusts a keg shoe at her anvil, with an eye cocked toward the horse she’s preparing it for.

Peter’s big move into full-time horseshoeing came around when his own farrier, Steve Prescott, told him he was leaving the area to relocated near Savannah. By that time, Prescott had helped Peter along with his own shoeing. Prescott also helped set Reynolds up to ride along with and learn from Dan Hutchinson, another veteran farrier in the area. It wasn’t long before Reynolds found himself shoeing horses other than his own, as he discovered that he not only had an aptitude for the work, but he truly enjoyed it.

7:28 a.m. While Peter was enjoying his new career, Angie recalls she was content with hers as well.

“I was a polo groom and it was the perfect job for me,” she says, noting that in gave her a chance to work with horses, something she is passionate about.

But being around Peter and his shoeing work piqued her interest in hoof care. She watched, learned and asked questions. At some point, she decided she wanted to go further and become a shoer herself.

You might expect that being married to a farrier would be perfect situation for a would-be apprentice. But that wasn’t the educational route the couple decided on.

“I didn’t think trying to teach my wife was the wisest thing,” Peter recalls. “Instead, we got her set up to ride with Dan Hutchinson, the same guy who taught me.”

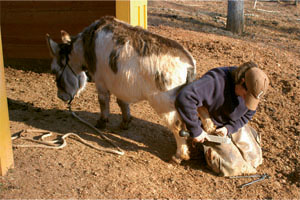

Angie drops to her knees as she trims the hooves of a miniature donkey. Angie is very careful with her approach to trimming hooves.

7:37 a.m. “I’ve always been really grateful to Dan for taking me on,” says Angie. “I played a constant game of 20 questions with him. I figured an apprentice was expected to be stupid, so I was never afraid to ask all kinds of questions and he was great about taking time to answer them.”

Angie says she’s also learned a lot from attending events of the Georgia Professional Farriers Association and the Alabama Professional Farriers Association. She not only learns from clinics, hammer-ins and other events held by the organization, but benefits from networking with other farriers she’s met.

“I always figure it’s better to make 10 phone calls if you’re not sure about something rather than go ahead and make a mistake,” she says.

7:42 a.m. Angie pulls into Mustard Seed Farm. She takes her shoeing box from the truck and walks across the yard to a small stable with a paddock.

“These are the barns you don’t see with Peter,” she says with a laugh. She explains that the majority of her clients are backyard horses, 4-H-Club ponies, “local show” horses and family pets. Peter, on the other hand, has more high-end equine athletes on his shoeing books.

Peter likes to have his shoeing rig well stocked.

“But that doesn’t mean I don’t do quality work,” she points out. “I operate on the philosophy that every horse deserves as good a shoeing job and hoof care as I can give him.”

7:53 a.m. Angie starts by trimming a mare inside the stable. The mare’s feet haven’t grown too much since the last trimming and she’s able to work fairly quickly. The only thing that slows her down is the mare’s 2-year-old offspring, who keeps trying to see exactly what’s going on. The youngster will find out soon enough, Angie notes. The young horse is next on her trimming list.

8:12 a.m. The horses’ owner joins Angie in the stable and holds the young horse for the trimming. As she works, Angie fills in the owner on how the feet are looking — fine — and also sets up some future appointments.

8:32 a.m. Both trims are quickly finished and the farrier moves outside to the paddock, where Clyde, a gelded spotted jack miniature donkey is waiting to be trimmed. Angie drops to her knees to work on the small animal, and — after cleaning out the hooves with a hoof pick — does almost all the actual trimming work with her rasp. Clyde is very cooperative and Angie is soon done. She puts her tools away, writes up a bill, collects a check for her services and is soon on her way.

8:41 a.m. Angie plans on stopping back by the Reynolds home to pick up her shoeing trailer, as she knows she’ll need her forge and anvil for the next shoeing job. She says she doesn’t expect the next stop to go as smoothly.

“I’m shoeing Pretty next,” she explains. “She’s been a very sore horse and I’m still working on getting her back into shape. It took me 2 1/2 hours to shoe her the first time.”

Angie drew four clips on this shoe. It’s for a sore-footed mare and the clips are to help keep the shoe on with a limited number of nails.

9 a.m. Upon her arrival at home, Angie makes a quick stop to check messages and refill her coffee cup. She also stops in the storeroom where she and Peter keep their shoeing supplies and picks up some shoes she expects to need later in the day.

She explains that she and Peter keep their shoeing businesses separate. They each have their own business licenses and keep their business accounts carefully separated from their joint personal accounts. She operates her business under the name Wildcat Forge, while Peter’s is called Ascot Forge.

Angie hooks her trailer up to her truck. “This was my birthday present from Peter,” she says, pointing to the Monetta trailer. “He bought it used and it’s just what I needed.”

9:23 a.m. After driving to the next stop, Angie sets up her shoeing rig and anvil in a flat area on a driveway. She then gets Pretty from her paddock.

She explains that the mare’s feet are very flat and that she tends to develop flares.

“She actually has pretty small feet once you get past the flares,” she points out. “But you can see that the white line is stretching out.”

Peter uses the horn of his anvil to adjust the branches of a keg shoe to better fit a hoof.

Pretty’s feet don’t look great, but Angie says the horse has made a lot of progress since she first saw her.

9:33 a.m. “When I started working with her, the horse was literally walking on her sole,” she says. “What I’ve been trying to do is get her to grow more hoof wall. It’s finally getting to the point where the hoof walls are starting to get back to the ground.”

The farrier cleans up the feet, then goes to work shaping shoes at her forge. She modifies a keg shoe, drawing four clips around the hoof wall. She hopes the clips will help keep the shoe in place with a minimum of nails. She explains that she wants to give the horse some support, but doesn’t want to drive a full set of nails because of how sore the horse is. She also points out that Pretty isn’t being worked right now, making her less likely to lose the shoe, despite the limited number of nails.

9:49 a.m. As she works, Angie is careful to keep the horse’s hooves low. She takes periodic breaks to let the horse set her feet down and rest. It extends the time of the shoeing job, but Pretty remains fairly cooperative. Once the first shoe is in place, the horse does seem to stand more comfortably.

It’s obvious that Angie has given a lot of thought to her approach with this horse. She carefully watches how Pretty moves. When fitting the shoe, she takes it back to the anvil several times for minute adjustments. She doesn’t really seem to see Pretty so much as a client, but more as a patient.

10:17 a.m. As she goes to work on the other front hoof, Angie points out that this one is in better condition than the first one. While it does flare laterally somewhat, it is more cone-shaped and has less separation at the white line. Angie is also able to get the shoe nailed on more easily.

11 a.m. After she has finished up the rest of the shoeing job, Angie walks Pretty up and down the drive a little before she leads her back to her paddock. While the mare is obviously sore, she does appear to move more comfortably than when she was first led from the paddock. Angie says she’s satisfied that progress continues to be made, but also says it will take more time to see if Pretty is able to return to work.

11:23 a.m. Angie once again swings by the house to drop her trailer off. She has one more appointment to keep today, but since it’s for a trim, she’ll save on fuel by not hauling the trailer — especially since the last barn is quite a distance from her home.

During the drive, Angie says her stops today are more widely spread out than usual. She ordinarily tries to set up her shoeing day to keep driving at a minimum, but admits it doesn’t always work out. Today, for instance, she needed to schedule two stops to arrive when owners would be present and on most days, she needs to have all of her stops made before school is over, so she can pick up the kids.

“When school is out, so am I,” she says.

12:17 p.m. Her final stop of the day is to trim a Palomino mare named Beauty. She admits that Beauty can be a handful.

“She is just not a particularly cooperative horse,” she says, diplomatically.

But today, Beauty appears to want to belie her reputation. Her owner is on hand to hold her, which may help. While Beauty does try to take her foot away from Angie a couple of times, for the most part, she stands quietly and Angie is able to trim her hooves quickly.

Angie takes a measured, careful approach to trimming. She’s been providing hoof care for most of the horses she sees today for some time, so the trims are more of an adjustment, done primarily with her rasp. She does use her hoof knife to remove flaky sole.

12:35 p.m. After collecting her check, Angie swings by G & H Horseshoe Sales in Marietta and picks up some nails for Peter. She then drives to In Your Dreams farm, where she meets her husband, who’s busy at work.

1:12 p.m. This is Peter’s third stop of the day. He trimmed three horses and one foal at his first stop, and trimmed two horses and shod another all the way around at his second. At this stop, he’s scheduled to trim one horse, shoe three all the way around and shoe three more with front shoes only.

For the next hour and a half, Angie and Pete will team up. He’ll do the trimming and nail shoes in place. She’ll clinch and finish feet and they’ll share shoe-shaping duties, although Peter will do the majority of it.

Peter shapes a keg shoe at his anvil. The farrier says that participating in shoeing competitions has greatly improved his forging skills and enhanced his day-to-day shoeing work.

The couple chuckle a bit over their tool preferences — particularly hoof knives.

“You’ll see a big difference between us,” says Peter. “I have Jim Poor hammers; I have Shayne Carter hoof knives. I want the best I can get.”

Angie, on the other hand, says she’s more selective. She wants good tools (she notes she spent $150 on her driving hammer), but also looks for good tools at a good price.

“I’ll buy my $9 Frost hoof knives and spend some time sharpening them the way I want them,” she says. “That way I can get the job done and not spend a fortune.”

Peter may have a “guy thing” about tools, but he’s also an avid participant in horseshoeing competitions. He’s a member of World Championship Blacksmiths, LLC. While he obviously enjoys the competitive aspect of the organization, he also says he’s learned a lot that has helped his shoeing.

“Furthering your education in this business is a must,” he says. “How you go about it is up to you.”

WCB competitions give him a chance to interact with other farriers who are expert craftsmen and horsemen, he says. And while WCB contests involved forging handmades, the forging skills and eye he’s developed by taking part serve him well in modifying keg shoes and other tasks that are a part of his daily shoeing work.

“Usually, modifying keg shoes isn’t as hard as people make it,” he says. “You take the closest size, look at the shoe and decide what needs to be done to make it fit the hoof, then do it as efficiently as possible.”

1:28 p.m. It’s quickly apparent that — for Peter at least — the approach is just about as simple as he makes it sound. He makes his modifications with a minimal number of heats in the forge, as well as a limited number of hammer blows.

As he works on the hooves of a big, bay horse, Peter explains some other things that he looks for as he works.

“I pay attention to the breakover pattern on shoes after I pull them,” he says. “That tells me a lot about how the horse goes.”

Peter also says how he fits the horse is dependent on a variety of factors, including conformation and the work a horse is expected to do.

Peter pays close attention to his shoe fit. He wants the hoof covered, with the shoe’s heels fitted all the way back to the heel buttresses.

“I don’t fit a hunter the same way I’d fit a school horse,” he says. “You need to fit them for the way they are ridden.”

The fit, he says, is something he focuses intensely on.

“If you get a good fit and cover the foot properly, you won’t need to use a lot of tricks,” he says.

On hunters and jumpers, Peter does use clips. He likes toe clips more than quarter clips, particularly when they’re needed on front shoes.

“A toe clip doesn’t push the shoe back,” he says. “I don’t mind quarter clips on back hooves as much, because they wind up being more forward on the hoof than they are on fronts.”

Like Angie, Peter is careful with his trimming. He tries not to take too much sole and is careful in nipping the heels.

“Nobody wants folded in feet and collapsed heels,” he says. “I want my shoes fitted all the way to the buttresses of the heels.”

1:47 p.m. Peter thinks a simple, basic approach works best on most horses.

“This isn’t rocket science,” he says. “If you get the angles right and get the foot growing evenly all around, you’ve taken care of the important things.”

To provide good hoof care, he says its important to look at much more than the horse’s feet. His background in riding, selecting and training horses for polo has served him well in his shoeing career, as it helped him understand how horses are built and move.

“I won’t try to ‘fix’ with my shoeing,” he says. “I’ll only try to fix things than can be fixed.”

2:17 p.m. Peter has a lot of hunters and jumpers in his shoeing book, so he uses a fair number of heart bar shoes. He buys heart bar blanks, which he creases, and pritchels himself. He then adds heart bar inserts. He does that work during “shop time” at home.

“I’m too busy when I’m on the road working to build and weld my own,” he says.

Peter and Angie both buy most of their shoeing supplies at G & H Horseshoe Sales. They both speak highly of owners Gary and Gene Hill, both for their customer service and knowledge of products and hoof care.

Peter is a big believer in keeping his shoeing rig well stocked. He shoes from a truck with a Stone Well shoeing body and checks his supplies every night.

“I like to have everything I’m going to need at hand,” he says. “I want to be able to restock my rig with what I need right away.”

2:30 p.m. Angie wraps up the clinching and finishing of a last hoof, then heads back for her truck. As she said earlier, “When school’s out, so am I.” She’s off to pick up the kids.

3:04 p.m. Peter points out that while the front feet on the horse he’s shoeing take the same size shoe, the right hoof is somewhat wider than the left. That’s fine with him.

“I won’t try to trim the feet so that they match,” he says, although he will modify the shoes for a proper fit. “They’re both good, sound and healthy feet. There’s no need to try and make them match.

3:21 p.m. Peter next trims the hooves of a New Forest Pony, an English breed.

Peter touches up a trim using his rasp.

“This is mostly a touch-up,” he says as he works. “I don’t square off the toe, even in the hinds. I don’t believe in it. It screws up the hock and can move up from there and cause problems in the hip.”

His goal, he says, is a “nice, oval foot.”

“I first came over from England when a lot of shoes were being backed up to the white line,” he says. “I didn’t think the feet looked as good as the feet of the horses back in England and now it seems a lot of people have gone away from that.”

3:48 p.m. Peter is now working on an older lesson horse. He mentions that he likes new Kerckhaert half-round shoes, particularly for older horses.

“These school horses work a lot,” he says. “This one usually just needs to be touched up a bit. He rarely has any issues that need to be addressed.”

Watching Peter work, it soon becomes obvious how he’s been able to work on so many horses today. There’s no wasted motion in his work and he drives nails in the same way he shapes keg shoes — with a minimum number of hammer blows.

But it’s that ability to “see” what’s needed to match a shoe to a hoof in a way that best suits the horse that really stands out. Horseshoeing clearly isn’t “rocket science” to him. It’s something he understands and is clearly very good at.

“I see some people I think are just trying too much on hinds,” he says, as he lightly touches his rasp to the hind foot of the horse who’s only shod in front. “They can’t look at a foot without thinking they’ve got to do something. A horse seems to grow a little longer on the inside, so they adjust the trim. Then it grows on the outside, so they adjust it again. All I do is level the foot off. The horse will be fine.”

4:24 p.m. Peter has finished up his last horse. After packing up his rig, he sits down and begins writing up his bill. As she waits for it, trainer Keely Ryan takes a moment to praise the farrier’s work.

Peter drives home a nail during a shoeing job.

“It’s through Peter that our horses are sound,” she says. “Ever since he’s been here, our horses have been the soundest they have ever been. We run over 100 lessons a week. Our horses are placing better in our shows and we’re really thankful for everything he’s done.”

4:19 p.m. As we head back toward the Reynolds home, Peter reflects a bit on how his career has developed — a career he never even envisioned not all that long ago.

“I’ve been lucky,” he says. “I’ve had good teachers and I’ve always been able to ask questions.”

He’s also always been thirsty for a chance to learn more about horseshoeing.

“It’s important to go to the clinics and pay attention to what the clinician has to say,” he says. “Don’t think you have to absorb the whole thing at once. Find something that you can hold on to and try in your daily work. I know my own shoeing knowledge has grown by being willing to listen with an ear toward applying what I hear to what I do.”

And the lessons, no doubt, will continue even after he gets home. With both Angie and Peter “Shoeing For A Living,” you’d have to expect there would be a little horseshoeing talk around the Reynolds family dinner table.

Post a comment

Report Abusive Comment