Shoeing feedlot horses can be more challenging than shoeing racehorses, show horses or trail horses. Most feedlot horses work constantly, in some of the worst conditions imaginable. Here’s some advice from four experienced shoers on what you can expect in shoeing feedlot horses and the importance of different environmental and weather conditions.

BAKER CHAPMAN

Lubbock, Texas

Baker Chapman shod for a feedyard in Lubbock, Texas, for 10 years and remembers the experience.

“Each feedyard is different,” he says. “At Lubbock, the alleys were paved and areas around the feed bunks were all concrete. It was really abrasive on shoes. It was difficult to keep shoes on because the unpaved areas got pretty muddy. It also depends on who’s riding. Some of the cowboys are good hands and others are more careless when they’re riding,”

Chapman planned his shoeing with those conditions in mind.

“I shod with clips and wide-webbed shoes. A lot of material packs up into the shoes and the footing is so abrasive that the shoes can wear all the way through the toe in about 6 weeks,” he says. “You have to keep these horses on a regular shoeing schedule. If a horse is ridden out there for just half a day without a shoe, he’d be out of commission for quite awhile.”

Tough Conditions For Hooves

Proper hoof care also meant more than regular shoeing, Chapman says.

“This yard had 30 horses and 6 to 8 cowboys,” he says. “A lot of them kept their horses’ feet cleaned out, but some didn’t. We had to deal with a lot of abscesses and gravel. There was a lot of gravel on top of the blacktop. If you don’t put quarter clips on the back feet, the horses tended to lose shoes. Their feet stay muddy because where the cattle get water, it’s always boggy.”

Chapman also says that horses that aren’t working are left in uncovered pens. If it rains, the ground in those pens gets boggy as well, resulting in soft hoof horn that won’t hold a shoe well.

“The ground at most feedyards is not as abrasive as the one I worked for,” he says. “Most of them have dirt alleys rather than concrete. The Lubbock one had grooved the concrete so cattle could keep their footing, but the horses had to be ridden on it whenever they sort or move cattle up the alleys. They had a rule that the cowboys couldn’t get out of a trot for safer footing, so they trotted those horses all day long up and down those alleys. You really had to take good care of those horses because they got used hard every day. Most of the cowboys rode a half day and changed horses.

“They might have four horses in their string and ride one a half day, saddle another and ride a half day, but some of them rode one horse all day, which is pretty tough on the horse,” explains Chapman.

Choosing Shoes

Chapman says that he used mostly wide-webbed St. Croix shoes for this type of shoeing.

“Most feedyards are not located on flat ground, because they want the water to drain away, so you have a lot of up-and-down slant to the alleys,” he says. “In the winter, these can get really slick, so I’d change to a rim shoe, like a St. Croix Xtra EZ. I always put a wide-web shoe on because the shoes wear out so fast.

“I used to use Kerckhaert shoes on these horses, too. Those shoes were very thick, with a lot of extra metal in them. I clipped them all the way around. But you don’t put a toe clip on these horses because the shoes wear so much that a toe clip will wear right off. I put regular wide-webbed shoes on in front and used clips on the hinds.”

Shoeing For Traction

Chapman says shoeing for traction was important during the winter months.

“I used to drive frost nails so the horses wouldn’t slip around so much,,” he says. “It can be dangerous out there when the manure and mud are frozen.”

He prefers frost nails over adding Borium to the shoes because on the grooved concrete of this particular yard, Borium can give too much traction to a horse that has to stop and turn quickly, possibly resulting in a wrenched leg.

“I used Borium for awhile for some cowboys from Kansas because they used it at a feedyard where they used to work, but the feedlot in Kansas didn’t have the grooved concrete,” he says. “Here, they hurt a lot of their horses, so it didn’t take us long to figure out that Borium wasn’t the best on concrete.”

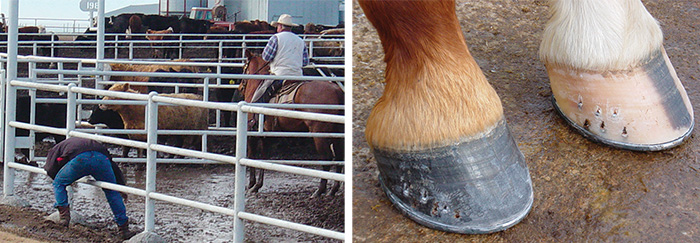

SHOES AND FEET TAKE A BEATING. The feet and shoes of feedlot horses can take a pounding. Above is the hoof of a freshly shod feedlot horse.

Chapman uses Mustad Frost Nails or a Borium-tipped nail, placing two at the toe and two at the heel. But he says the combination of concrete and frozen ground is so abrasive, that he sometimes has to replace those nails prior to the next shoeing. He says he’s also used studs in the winter.

“I’d drill some of the shoes before I went out there, tap them at the heel and put in a stud,” he says. “Sometimes, when it was really icy, I used Mustad Drive-In studs, to help the shoes wear a little better. But you wanted to make sure you don’t have big studs on those shoes or the horse was apt to twist a fetlock joint.”

Feedyard Foot Problems

Feedyard footing can be hard on the foot, Chapman says, particularly if material gets impacted inside the hoof and presses against the sole.

“Feed and manure is fairly soft, but mixed with dirt it can become hard as a brick,” he says. “It’s quite abrasive and can take a lot of the sole out. The frogs on these horses are really thin. I never trim much frog and always leave a a little foot in case they lose a shoe — so they won’t get sore just riding back to the barn.”

Surprisingly, though, Chapman doesn’t see a lot of thrush, despite the wet conditions these horses work in. He thinks that may be because most of the horses start out with good feet.

“A horse with flat feet or a thin wall won’t hold up at a feedyard,” he says. “Most of these horses have pretty good, strong feet, with a lot of wall. You don’t see many fine-boned horses here.”

Other problems do crop up though.

LOTS OF WEAR. Here are the feet of the same horse, 6 weeks later.

“Some of the horses that have been out there for years develop stringhalt, and some get inflammation of the coffin bone from the concussion and constant pressure of having the foot packed with material,” he says. “Every time a foot is packed up like that, it compromises blood flow to the sole and circumflex artery.”

Ringbone is another common long-term problem for feedlot horses. Chapman says proper shoeing is important to help prevent as many of these problems as possible.

“Balancing the foot is very important. I make sure the horses are balanced, because you sure don’t want any quarter cracks developing from improper pressure on the foot,” he says. “If you don’t shoe them level, they’ll be more at risk for quarter cracks — just from being ridden on those hard surfaces. I back the toes up on a lot of these horses, too, just to give them easier breakover.”

Although some shoers might be tempted to put pads on these horses, Chapman recommends against it.

“Pads can increase the problem of material packed in the hoof,” he says. “It packs up between the shoe and the pad and can actually pry your shoe off,” he says.

He says it’s almost impossible to keep material from working up under the pads in these conditions and also thinks they might increase the chance of a horse developing thrush.

Dry Better Than Wet

The softer feet caused by wet conditions combined with boggy footing mean that a farrier needs to be concerned about losing shoes. And while summers can be dry in Texas, that generally doesn’t cause a problem for the feet of these horses.

TOUGH?WORK. This is a shoe taken off of the same hoof. Note the crack all the way through the toe of the shoe.

“I’d rather it be dry than too wet; they lose more shoes in the wet conditions,” says Chapman. “Even if it gets dry in a drought, their feet stay in good shape because there’s always moisture in the cattle pens. But if they ever lose a shoe, they wear the foot away so quickly that you might have to let them go a few weeks to grow enough hoof to put a shoe back on.”

Chapman has found that shoeing in feedlots means he’s often shoeing new horses as cowboys as well as their mounts change. He says that makes it important to pay attention to safety issues. Feedlot management helps, he says, by trying to make sure that really rank horses aren’t brought into the lots and by making sure horses can be tranquilized when necessary.

“You definitely don’t want to handle some of these horses without tranquilizers,” he says. “There’s no sense in getting hurt for a $70 shoeing job.”

The feedlot at Lubbock is only 5 miles from his shop and had 30 horses he shod regularly, so he had a routine worked out. Horses that needed shoeing or had lost shoes were tied up waiting for him when he arrived. That meant he didn’t have to go out and search for cowboys with horses that needed to be shod.

NYLE HENDERSON

Ness City, Kansas

After training and shoeing horses for many years in Colorado, Nyle Henderson and his wife moved to western Kansas 7 years ago. He shoes for Lane County Feeders, a feedlot that handles 42,000 head of cattle.

“There are a lot of horses at this yard and they are all well broke and the cowboys are helpful,” says Henderson. “If I’m shoeing and it’s one guy’s day off, the others bring his horse up and clean its feet for me.

“Lane County Feeders is a cowboy lot, and the guys know how to take care of their horses. Horses are used for everything. They push cattle up to the processing chute and do everything on horseback. In some other feedlots they use 4-wheelers to push cattle down the alleys and just use horses if they have to. But here, everyone uses horses. They ride the pens early in the morning, and may change horses at noon. These horses are worked steady.”

FEEDLOT FARRIER. Nyle Henderson shoes a horse at Lane County Feeders in Ness City, Kan. Henderson says that while the horses used in feedlots are worked hard, he’s found their feet to be surprisingly healthy.

One thing that surprised Henderson when he started shoeing feedlot horses was that most of them have healthier feet than some of the show horses or racehorses he worked with.

“The cowboys make their living on these horses and are careful with them,” he says. “They want the horses to last and they don’t have a lot of money to spend.”

He rarely sees a case of laminitis in feedlot horses.

“These cowboys have had many of these horses a long time and have kept them pretty sound,” he says. “I appreciate that and was surprised, because they have such tough working conditions in the mud and manure. The footing is really deep a lot of the time, and slows their feet down, challenging their mobility.”

Snug Fit

If a horse’s front feet come out of the mud a little slow, the horses tend to catch the front shoes with the hind feet. “So I don’t leave anything sticking out,” Henderson says. “I don’t shoe tight, but I shoe snug.”

He tries to make sure the horses can move easily. When he first started at the lot, he found that horses were tripping, not getting their front feet out of the way quickly enough, and pulling shoes.

“If the shoes are too big, the horses can’t move well,” he says. “It’s like a person trying to be agile with a pair of overshoes on.

“These horses work for a living. I try to shoe a horse for how he travels. I don’t want to change him — just try to keep him free and moving. I don’t change him to where he shortens his stride at all. I just try to speed it up a little bit,” he explains.

He feels long toes and low heels lead to problems.

“Coming from mountain country, I’ve always stood my horses up a little more and enhanced the breakover of the foot by shortening the toe. I don’t roll the toe unless I have to, but I sure don’t leave any extra. With a quicker breakover, the horse can recover his balance better. He’s not hitting himself and it’s easier on the foot. The horse moves cleaner with more lift in the foot and not dragging his toes. A lot of horses that people think are clumsy become more agile when you shorten that toe,” he says.

Rim Shoes Preferred

He doesn’t use many wide webs or plates on feedlot horses.

“I don’t like a horse to slip around, so I use rim shoes,” he says. “It gives a little more traction and cleans out better. I use mostly St. Croix shoes. The inside of the shoe is tapered. They fill up, but they’ll clean out better.”

He fits the foot closely and and uses the rear nail holes because he feels this helps keep a shoe on. Since he brings the toe back, he may not use the toe nail holes.

“I don’t want to lose shoes. When a shoe pulls off, it always damages the foot,” he says. “I clinch them pretty tight.”

While the horses are ridden every day, Henderson says most of the cowboys ride several horses and rotate them out of pasture for a rest after a couple of shoeings. He shoes most of the horses every 8 weeks.

Avoiding Calks

For winter shoeing, he puts four spots of either Borium or Drill Tech on the rim shoes — at the heels and each side of the toe.

“I like that better than using drive-in calks or screw-in calks because you can keep the foot closer to the ground and it’s easier on the foot. With too much height and traction, you can get too much twist in the foot when they are working fast.”

“I’ll have the shoe very close to proper shape before I put the Drill Tech on,” he says. “You don’t want to try to shape them afterward. That stuff is so hard it will eat a hole in your hammer. I usually preshape the shoes and put it on ahead of time, because it takes an extra 30 minutes. I go to the shop in the evening and do three or four sets, to save time at the feedlot.”

SHOP?WORK TIME SAVER. Because Nyle Henderson knows most of the horses he shoes at Lane County Feeders will need added traction in winter, he shapes the shoes as close as he can to what will be needed and adds Borium or Drill Tech in his shop, before he goes to the feedyard. He says he can do this because he’s familiar with the shape of the horses’ hooves already. He warns that it’s hard to modify shoes very much after the tube metal has been added.

Henderson says because he’s familiar with the horses, he can shape the shoes pretty close to what he’ll need. He also carries a couple of extra sets of shoes with Borium or Drill Tech applied to them in his truck during the winter and keeps a tube of Drill Tech with him in case the feedlot has a new horse that needs to be shod with it. He finds it quicker to apply with a torch than in the forge.

“I tell the cowboys that if the horses are shod this way, they better make sure the horses get along if they’re penned together,” he says. “If they kick with this, they can really tear up another horse.”

Using Wedge Shoes

If a horse has problem heels, Henderson often uses wedge shoes.

“I use wedge shoes on a horse that’s foundered and has underslung heels — when I want to bring that heel back as much as I can,” he says. “A lot of times you can’t build much heel on these horses. It will collapse because it’s too thin and may have lost its bars. So you can go ahead and take the heel down to where it’s solid, then use a wedge shoe to get the needed elevation. Some guys do that with pads, but I don’t like to use pads in the feedlot because you could get a lot of thrush.”

Henderson usually shoes feedlot horses on an 8-week schedule. Henderson actually has one feedlot on a schedule that has him doing all the horses at one time.

“It might take me 2 or 3 days to do them all, but it helps my schedule and also helps them keep track of where they are on the feet.”

Keeping Feet Clean

In Kansas, the alternately wet and dry conditions in a feedlot can make a hoof brittle and prone to cracking.

“We get a lot of scratches sometimes because these horses are working in deep footing,” he says. “The guys that take good care of their horses don’t have as much of a problem, because when they come in to put their horses away after work, they hose them down and clean the legs. I recommend that and most of the guys at the feedlot who depend on their horses for a living will really work with you and listen to you. If I tell them they need to clean the feet every day and put something in there to prevent thrush, they’ll do it.

“Sometimes in early summer when flies are bad and the horses are stomping a lot, they loosen the nails. Most of the feedlots use fly control measures, however, and I actually have less trouble with their horses,” says Henderson.

“We get some problems with thrush and some sole abscesses since they are working on gravel feed lanes and are on and off cement a lot. You see a little more sole bruising.”

Henderson says because the cowboys understand the importance of cleaning their horses’ feet, he doesn’t see much thrush, despite the fact that the horses spend a lot of time standing in mud and manure.

Another problem he runs into is gravel infection when sand enters the bottom of the foot at the white line and the infection eventually works up between the hoof wall and the inner tissues, to break out at the top of the hoof.

“That’s another reason I don’t like a wide-web shoe,” he says. “Coarse sand will come in behind it, right at the white line at the toe. It will work in under that wide web shoe and then go right into the white line. There’s a little pocket in there and it packs full of sand. I’ve never seen as many gravel infections in any other part of the country.”

THERE’S ALWAYS MUD. Even in otherwise dry conditions, horses working in feedlots are likely to encounter deep, shoe-sucking mud in watering areas. Nyle Henderson finds shoes stay on so long as he pays attention to a snug fit and uses a thick nail.

JASON OWSTON

Eckley, Colorado

Jason Owston shoes a lot of feedlot horses and says most of them don’t have soundness problems because they have to make a living and the cowboys need a sound horse.

“I shoe these horses like any others except not quite as full in some conditions. You don’t want them sucking shoes off in deep mud. In the summer I use a rim shoe. In winter, I use a lot of Drill Tech for better traction. I put four spots on each shoe and do it in the forge. Some feedlots just want toes and heels; what I use depends on what they prefer. On a horse that’s borderline sound, I may not use Drill Tech on the toe if I’m rockering the toe. I want them to breakover and go forward as easily as possible,” says Owston.

Keeping feedlot horses on a schedule is important, since they tend to wear out shoes and lose them if they go too long before shoeings, Owston says.

Big Account

“If they lose a shoe, they’re in trouble until you get there to take care of it,” he says. “I have one account where I take care of 100 head, with 60 of them shod all the time. Each cowboy has three horses and rotates them. It’s important for the shoer, in an outfit like that, to be the eyes and ears and take the responsibility of keeping track of those horses — especially at a feedyard that supplies the horses.

“This outfit depends on me to make sure that when horses are brought to me to be shod they are sound enough to do the work for another 6 to 8 weeks. If not, we pull the shoes, trim them and turn them out for awhile. If it’s a back problem or a bruise, we address it and then the horse won’t be ridden until it heals up,” he says.

There can be a lot of injuries since the horses are exposed to so many different conditions, but Owston also finds that most of them start out sound with good feet.

“Feedlot horses are the major part of my business, but also one of the most straightforward, with the least problems,” he says. “They tend to have sound feet because they are used all the time, getting regular exercise. Their feet grow well and need reshoeing every 6 weeks. We try to rotate the horses in and out every 6 or 7 weeks to give them a break, but some will be in for two shoeings in a row.

“Some shoers think of a feedyard as a volume account where they can shoe a lot of horses in a day. I don’t. I want to do just as good a job on these horses as my top-end reining horses. Some of the horses are getting up in age and maybe borderline on staying sound. I shoe some feedlot horses that are 19 or 20 years old. They need a little extra care to keep going.”

Shoeing For Support

Owston says he’ll try different tricks to help those old joints move a little easier.

“I may rocker the toe instead of setting a shoe back, just to support that toe.” he says. “Those horses put so many miles on that they’ll wear a shoe out in 6 or 7 weeks, so I want to protect the foot as much as I can.”

Feedlot Shoeing Priorities

Good sound shoeing and keeping horses on a schedule are the keys to successful feedlot shoeing, according to Owston. He also keeps the lines of communication with cowboys open.

“I talk to the guys riding the horses so if they know of a problem I am not seeing, they can tell me about it,” he says. “A lot of times you never get to see the horses working. They’re tied up when you come to shoe them.”

Shoeing conditions in most feedlots are good. At one yard, he even gets to do his shoeing in a nice barn.

“There are heaters above you and crossties for the horses,” he says.

“The horses are tied in there when I show up and I don’t have to catch any horses. When it’s nasty outside I can be in there working in short sleeves.”

Not all feedyards have quite as nice a workplace, but Owston says it’s important to insist on safe and proper working conditions.

“You should insist on having a good place to work with good lights and good footing,” he says. “A feedyard is a business; they are interested in the bottom line. In the big yard I work for near Yuma, I’m in there all day Tuesdays and a half day on Friday, every week. It’s only 7 miles from where I live, so it’s pretty handy.”

Owston enjoys the feedyard work and knows he plays an important role in keeping the horses sound and able to do their jobs.

RUSS WIEGERS

Leoti, Kansas

Russ Wiegers has a horseshoeing business and Double Bar One, a farrier supply store. His wife, Cathy, runs the store. Wiegers has been shoeing since 1978 and for a long time, most of his shoeing involved feedlot horses. He doesn’t do as many now, but still shoes about 40.

“The feedlot people are starting to realize the importance of safety,” he says. “The horseback part of feedlot work is a major part of the injuries, so good shoeing is essential. I did a clinic for the Kansas Livestock Association on feedlot safety. They had three sessions just on shoeing for safety — for traction and balance — and how important it is to keep horses shod properly and on schedule.

Wiegers believes feedlot managers are beginning to realize that in the long run, it’s cheaper to have a good farrier and minimize the problems and safety risks.

Like other feedlot shoers, Wiegers finds the horses and their shoes can take a beating.

“It’s not uncommon to have shoes completely worn out and broken in half after 6 weeks,” he says. “Knowing the riders and what the horses will be used for in the feedlot can be a factor in how you shoe the horse and what kind of shoe you select.”

He often chooses the heaviest shoe he can get away with and still keep the horse balanced. He also sometimes uses Drill Tech to help the shoe last longer.

“The shoe I use 90 percent of the time, however, is a rim shoe,” he says. “I’ve used some toe and heel shoes, but they tend to wear down a little too fast, and toward the end won’t have any traction. The rim shoe has just a bit more traction.”

He also finds the hooves of these horses are surprisingly healthy.

“You’d think that with the manure and conditions in which the horses live and work you’d see bad feet but they are probably more healthier than any other horses I shoe,” he says. “The continual exercise helps, and the compaction — the constant, even pressure on the sole from always being packed with mud, manure and rocks. I think this supports the foot like a natural pressure pad. There is also more hoof growth and a healthier foot because of the exercise and better blood circulation. These feet don’t have many bruises or abscesses if they are shod correctly.”

When trimming, he leaves as much sole for protection as possible.

“I’ve learned that horses are a lot tougher than I thought, in their ability to overcome injuries while being worked,” he says. “The cowboys often have to keep using these horses even when they are sore. The mud gets pretty deep. In one day a horse works in many different conditions — good ground, deep mud, concrete, gravel, etc.”

Some feedlots have company horses and at some outfits the cowboys use their own.

“The company horses get used pretty hard, but I have some I’ve been shoeing for 15 years and they’ve held up pretty well. It takes a good horse, with a good mind and fairly good feet and legs,” he says.

“You don’t always get that, since high dollar horses aren’t used in a feedlot. But there are some good horses there,” he says. “Some cowboys ride young horses a few years in feedyards for training, then sell them. Those horses are bombproof; they’ve been around the noise of big trucks and have seen a little bit of everything.”

Shoeing For Conditions

Weather conditions can be a challenge. Kansas has hot summers and cold winters.

“In summer we have to contend with dust — and have to watch the health of the horses because of the dust,” he says. “A good farrier tries to keep the management aware of what’s going on with the horses and their general health. The only time we have real foot problems is when it’s muddy — a long winter with a lot of snow or rain. We have quite a bit of shoe loss in the spring with thawing or spring rain. It can be boggy for weeks at a time.

“At times you have to shoe them fairly close in front. I also put quarter clips on quite a few hind shoes in some of the yards if the cowboys are riding harder, on hard ground, so they don’t lose the back shoes,” says Wiegers.

He feels feedlot shoeing is a good place for beginning shoers to get some experience.

“You can learn a lot about hoof balance and about working with people. That’s sometimes the hardest thing to deal with. In a feedlot you are dealing with the cowboys and the management, and it’s a good place to learn to shoe horses.”

Post a comment

Report Abusive Comment