Farrier Takeaways

- The slide phase of a horse’s stride is of utmost importance for absorbing concussion and reducing the potential for injury. Therefore, as farriers, we need to be proactive in our attempt to create slide with the shoes that are applied on horses working on synthetic surfaces.

- Due to the abrasive ground force reaction of synthetic footing, we must pay close attention to the wear plates in our aluminum shoes. As the aluminum becomes worn, the steel wear plate can become a toe grab, creating even more traction.

The study of synthetic footing remains the frontier of the sport horse industry. In my opinion, synthetic footing is the sporthorse farrier’s greatest challenge. There is little scientific data available to guide farriers. Mostly, we have our own experiences and those of our colleagues to what works and doesn’t work for horses that are performing on synthetic surfaces.

My experience comes from 24 years of shoeing and what I’ve learned from mentors, colleagues and horses along the way.

I’m the founder of the multi-farrier practice C-Cross Farrier Services in Colorado. We are the official farriers of the Colorado Horse Park since 2015. We cover an average of 75 days of hunter/jumper shows each year. We also worked the 2016 FEI North American Young Riders Championships, the 2017 FEI World Cup and Dressage Finals in Omaha, Neb., as well as the 2018 American Eventing Championships, all of which were shown on synthetic footing.

We’ve had the privilege of tending to horses from all over the United States, Canada, Mexico and other countries around the world. Additionally, each winter, a portion of our clientele leave the high desert of Colorado and spend the winter in either Florida or California.

The way we shoe our horses must adjust for that dramatic change in environment. Over time, I have discovered commonalities that work and don’t work for me regarding environmental changes and synthetic surfaces.

This article will focus on answering the questions: What is synthetic footing? What are the challenges farriers face with horses that perform on it? What are some of the options for keeping horses sound and comfortable while competing on synthetic surfaces?

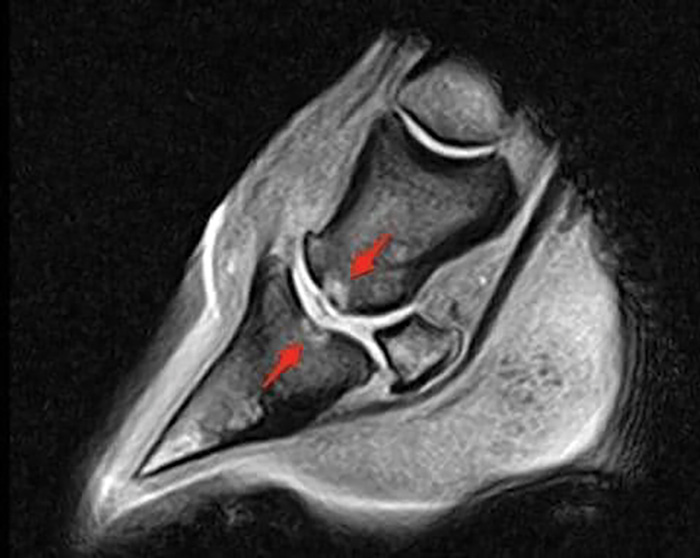

This MRI is an example of a bone bruise on the coffin bone and short pastern that occurred because of rapid deceleration on synthetic footing.

What is Synthetic Footing?

Synthetic footing is a mixture of three key ingredients — sand, textile and water. Sand is the key ingredient in all synthetic footing, but not all sand is created equal.

In the United States alone, there are more than 10,000 different types of sand, most of which are not good, or even adequate, choices for arena footing. Sand is broken down into two categories — natural and manufactured sand.

Natural sand. Natural sand has eroded from mountain rock and mined where it was deposited.

Most sand is comprised of silica, which is the breakdown of quartz crystals. These particles have been sifted and transported by water, making them round or subangular in shape. This type of sand is resistant to weathering and breakdown is due to a chemical process and chemical hardness. It will last longer as arena sand.

Manufactured sand. Manufactured sand comes from rock quarries, where the smallest particles, known as fines, are gathered and sold as sand. The particles range in size and composition. They are not the hard quartz grains of tumbling river action, so they can be softer and break down to dust much easier than your typical natural sand.

If we break it down further, each particle of sand has a shape that is round, angular and subangular.

- Round particles create voids, which offer cushion to horses as they engage the ground, but they can often roll like ball bearings and make the surface unstable.

- Angular particles have sharp edges and fit together tightly. This provides stability and traction, but angular particles also can compact and harden the surface.

- Subangular particles have the sharp edges worn off. This allows them to nest together, resulting in a surface that is less likely to compact and provide more stability.

Textile. There are various types of textiles such as polyester, shredded carpet and felt that are added to the silica to create synthetic footing fibers. When sand and textile are combined, it creates a firm surface that absorbs water and stays consistent over time. Nevertheless, this combination is abrasive, which most farriers have noticed from the polished appearance of the shoes that we pull off. In general, textile changes the composition of the footing so that horses are more likely to stay on top of the surface rather than down in it.

Water. Water creates a molecular bond between the sand particles and the textile. Water stays consistent from 33 degrees to 160 degrees Fahrenheit. However, the amount of water that a synthetic surface receives is an important, yet not always controllable variable. Synthetic surfaces need a lot of water to perform optimally.

When the surface is too dry, it loses stability. When it’s too wet, it can have even less movement resulting in more traction.

Environmental Challenges

Horse show producers love synthetic footing because it wears and drains well. However, what works well in a humid environment, such as Palm Beach International Equestrian Center in Wellington, Fla., doesn’t always work the same in a dry, arid environment such as Desert International Horse Park in Thermal, Calif.

The environment is an important factor. Footing that receives a lot of rainfall day-to-day is going to respond differently than a place that’s dry where the primary source of moisture comes from a water truck. Therefore, horses that are working in Wellington or Ocala, as opposed to Thermal or Scottsdale, Ariz., are on a different surface. Even though the textile might be exactly the same, chances are the sand and the amount of water are much different. As a result, the ground force reaction will vary from venue to venue, not to mention how the footing is prepared by the grounds crew is also important.

With so many variables from one venue to another, it is difficult to know how to prepare our horses for success. Fortunately, there is hope. Susan Stover, veterinarian and professor of anatomy, physiology and cell biology at the University of California, Davis, and her colleagues are part of the developing field of footing science.

Stover’s research group is one of several around the world that is interested in footing and its management to optimize surfaces and shoeing to prevent injuries. The team believes that if we can raise the standard of surfaces, then we can decrease the number of injuries.

In 2014, the Fédération Equestre Internationale (FEI) produced a white paper presenting the challenges of identifying the characteristics of the ideal surface and then standardizing it for competition.

According to the paper, the surface needs to be firm enough to support the horse while soft enough to dampen the load. It must be responsive to return en-ergy effortlessly while providing enough purchase for propulsion and enough slide for the landing.1

This is no small task. The number one goal of those researching footing is injury prevention. The number one goal for us as farriers should be the same. In turn, shoeing for injury prevention in synthetic footing is the task handed to farriers.

Common Synthetic Footing-Related Injuries

Research shows that jumpers, especially elite jumpers — those jumping 1.40 meters and higher — most frequently injured their suspensory ligaments of the forelimbs.2 Other frequent injuries include:

- Strains and tears of the deep digital flexor and superficial tendons, the medial and lateral collateral ligaments and the impar ligament of the navicular bone.

- Inflammation of the coffin joint.

- Deep tissue or bone bruising.

Although this article primarily focuses on hunters and jumpers, it’s worth noting the rise in proximal suspensory injuries in the pelvic limb of dressage horses. These injuries could be associated, as well.

A myriad of other injuries take place in the hock, stifle and sacroiliac joints that could also be related to the footing.

The most common lameness that we’ve seen in the past 7 years at Colorado Horse Park is acute inflammation of the coffin joint. This lameness is new since the change to a synthetic surface. The lack of slide that occurs on impact after landing in synthetic footing causes the foot to come to an abrupt stop. This is thought to result in movement of the coffin bone within the hoof capsule, creating inflammation of the navicular region, as well as the sensitive laminae.

Rapid deceleration not only has an effect on horses’ feet and limbs, but also on their shoulders and neck. As these athletes tend to get sore, they start to compensate and use their bodies in an abnormal manner, which further magnifies poor performance and raises the potential of other injuries. We see this after days of consistent showing.

The best training programs are well aware of the effects of the surface on their horses and the risks involved with over-showing their horses. Yet, the horses are required to perform on this surface and the industry must adapt.

Traction Shoes and Their Complications

Preparing horses for competition requires us to know as much about the surface they will be performing on as we possibly can. My top priority is keeping horses and riders safe while still being competitive. Decreasing traction on front feet, and sometimes hind feet, is essential.

Shoe selection matters. In most cases, rim shoes, concave, bar shoes, improper nail fit, excessive wear plates and traction have proven to be detrimental on the front feet of hunters and jumpers while performing on a synthetic surface.

The bar of a bar shoe tends to act like a brake in synthetic footing. A set-down bar seems to help. However, a horse that requires a bar shoe will receive a pad from C-Cross Farriers to partially counteract the bar and create slide.

The bar of a bar shoe tends to act like a brake in synthetic footing (Figure 1). A set-down bar seems to help, but if a horse requires a bar shoe, we are careful to either pour the foot or attach a pad as an attempt to counteract and create slide.

Historically, the front feet of hunters have been shod in aluminum to enhance movement and promote a flat knee. Studies have shown that aluminum can have less slide than steel.

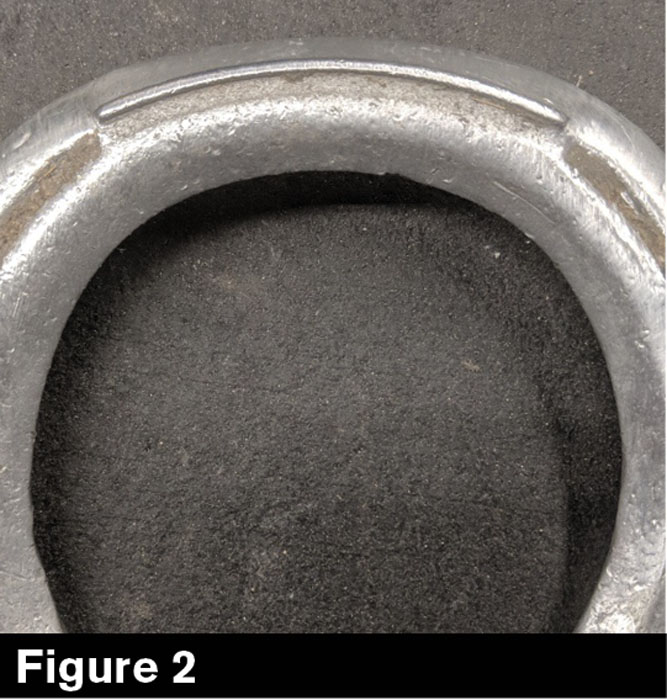

Additionally, I have found that horses tend to wear the aluminum out of the toe on synthetic footing. What’s left is a steel wear plate that can turn into a toe grab.

Oftentimes, horses will wear out the aluminum in the toe of a shoe in synthetic footing, exposing a steel wear plate. This wear plate quickly acts as a toe grab.

I pull off far more aluminum shoes, such as Figure 2 on horses with aggravated coffin joints than any other shoe.

Before synthetic surfaces were common, we used traction because it was thought to give a horse more confidence. Today, I wonder if too much traction on a synthetic surface leads to a reluctance to perform.

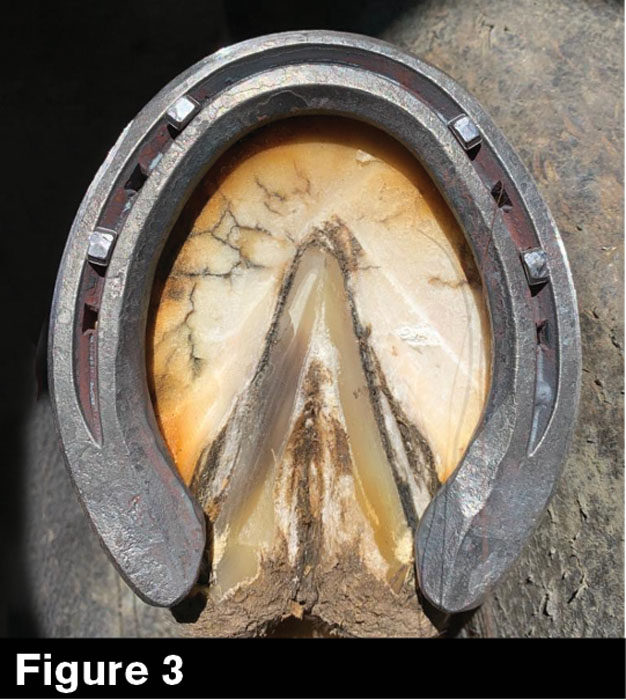

The concavity of the inner web, accompanied by the fullering, creates a shoe that cuts and penetrates through the top of the surface, leaving a perfect imprint of the foot in the surface. The result is minimal to no slide.

Full rim shoes were the most common selected for horses showing at the Colorado Horse Park until it changed to a synthetic surface. The concavity of the inner web, along with the fullering, enables the shoe to cut and penetrate through the top of the surface, leaving a perfect imprint of the foot in the footing, resulting in minimal to no slide (Figure 3).

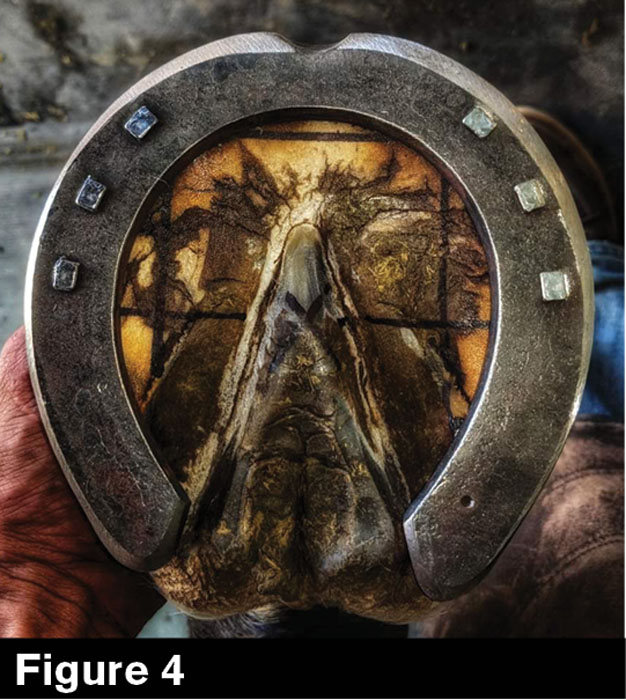

Plain-stamped shoes often provides just enough slide for a horse that has had too much traction resulting in coffin joint inflammation. Once nails have been placed and nail height is satisfied, the nail heads are rasped off.

Intentional Shoeing

As previously mentioned, farriers shoeing for synthetic surfaces must have the goal to create as much slide as possible with the shoes that we apply. Often, plain-stamped shoes can provide enough slide for a horse that has had too much traction resulting in coffin joint inflammation (Figure 4). A plastic or leather pad can also create flotation and help horses stay on top of the footing. Once nails have been placed and nail height has been satisfied, we will rasp nail heads down until they are completely flush with the ground surface of the shoe. I like using concave nails as they require minimal to no rasping.

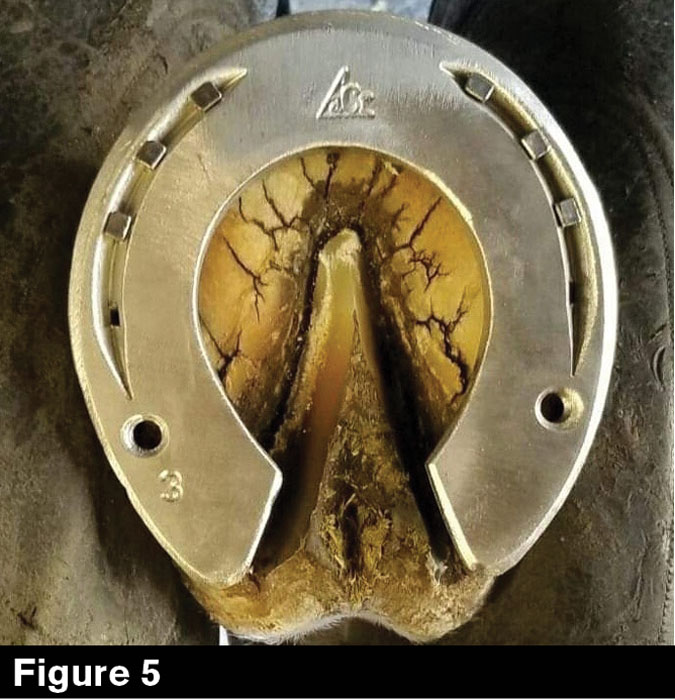

When aluminum shoes are being used on hunters or jumpers, I suggest using those without wear plates. Unfortunately, selection is fairly limited in terms of aluminum shoes without wear plates, so pay close attention to what the wear plate looks like at the end of the shoeing cycle. In an arid, dry climate where large amounts of water are needed, synthetic footing seems to have slightly less grip. Therefore, the aluminum doesn’t seem to be as sticky as it might be in a humid, wet climate (Figure 5).

Aluminum shoes do not seem to be as sticky in an arid, dry climate as they are in humid or wet climates. Consider the width of the section. Although a wide section keeps feet on top of the surface, it can also create more traction.

Consider the width of the section. Although a wide section might keep a horse on top of the footing, it might also create more traction and less slide. A section that’s too narrow will likely cut through and grab the footing. I have colleagues who like Classic Rollers on the fronts of their jumpers as they believe it puts less steel against the surface and encourages slide.

Rim pads are common in Florida as they are thought to keep horses up out of the footing, yet we rarely see them used in Colorado. Team Sweden won Olympic gold in Tokyo on a synthetic surface with horses that were barefoot. As you can see, there is a lot to consider when choosing the right set-up for each particular horse.

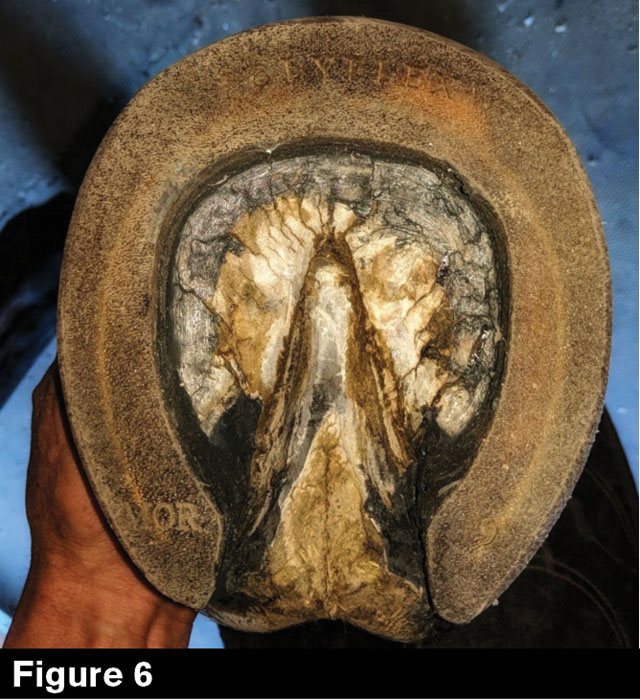

Polyurethane shoes are an option that encourages slide in synthetic footing.

Polyurethane shoes are another option that encourages slide in synthetic footing. (Figure 6) At this time, minimal scientific research has taken place to prove the capabilities of urethane shoes. Nevertheless, they are being used by top U.S. farriers and are thought to help dampen the load on impact and create slide. I have had great results using Polyflex shoes on my hunters. I have used them on jumpers, as well, and the horses have responded positively.

Finally, I have seen tremendous im-provement by using mechanics to reduce leverage and traction while encouraging vertical depth and a strong hoof capsule. An example of mechanics that I use would be the French rocker toe (Figures 7a and 7b). I have found that this allows the foot to better pass through the footing in the landing phase of the stride. It also encourages breakover while still fitting the toe. As previously discussed, how the section is manipulated and fit are dependent on the horse and should be considered in detail before shoes are applied to a horse working on a synthetic surface.

A French rocker toe can help reduce leverage and traction. The proper width of section is dependent on each horse. It should be given serious consideration before applying shoes for synthetic footing.

Conclusion

The challenge of shoeing horses for synthetic footing is real. Maybe one day there will be a standardization of arena surfaces, but until then we must continue to educate ourselves about footing and how it varies from place to place.

There are endless opinions as to how a horse should be shod or trimmed for success on a synthetic surface. Nevertheless, until we have scientific research to back these opinions, we are left with doing our best to prepare our horses to prevent injury while also being highly competitive. Our ability to embrace the challenge of this new frontier known as synthetic footing is critical for the long-term wellness and success of the horses in our care.

References

1. Hobbs S, Northrop A, Mahaffey C, Martin J, Clayton H, Murray R, Roepstorff L, Peterson M. (2014). Equine Surfaces White Paper.

2. Murray RC, Dyson SJ, Tranquille C, Adams V. Association of type of sport horse and performance level with anatomical site of orthopedic injury diagnosis. Equine Exercise Physiol 7, Equine Vet J Suppl 2006;36:411.

Post a comment

Report Abusive Comment