Farrier Takeaways

- Arabian show horse farriers must ensure that the shoe packages and measurements meet the strict rules.

- Zach Morris typically keeps the horses on 5- or 6-week shoeing schedules. However, because of the shoeing rules, horses heading for shows sometimes are left to go long to ensure they fall within the appropriate hoof measurements.

- Since most of Arabians have high-low, Morris must adjust his shoeing packages to accommodate them.

These are busy days for Zach Morris.

The Lyons, Ore., farrier is logging significant miles — both on the road and in the air — as several of his clients will be making the trek to Tulsa, Okla., for the United States National Arabian & Half-Arabian Championship Horse Show. With a little more than 2 weeks before the show, Morris has his work cut out for him.

After spending the previous week in New England, Morris will be on the opposite coast for the upcoming weekend as he prepares more clients’ horses that are stabled in the Seattle, Wash., area. In the meantime, clients closer to home at Prestige Farms in Hillsboro, Ore., are on his immediate mind on this “Shoeing for a Living” Day.

A big part of ensuring that Morris’ work is performed at a high level is the help that he receives from associates such as Lillian Wenham, who accompanies him today.

“It’s really easy to be successful when you have good help,” he says. “It’s not just the physical aspect of it. Their abilities to perform tasks well allows my mind to go in a completely different direction for a longer period of time.”

When help isn’t available, performance can suffer.

“When you’re struggling to find help, there’s a point when you can’t do it at the required level,” Morris says. “What do you do? Should I scale back to where it’s manageable for one person?”

Like many farriers, Morris’ bottom line is feeling the effects of inflation as escalating costs are taking a healthy bite out of his profits.

“I’m having a hard time keeping up,” he says. “I went up roughly 7% in January. The majority of people understood, and some were even happy that I’m running my business the way it should be. There are those who lost their minds. We’re talking about a couple of Starbucks trips here. Historically, my price increases haven’t been that big across the board, or I’d sneak one in by raising the prices of my pads and keeping everything else the same.”

A band is used to secure the shoeing package to Mo’s foot.

Keep ’Em Legal

Morris navigates his Dodge Ram 3500 pickup into the driveway at Prestige Farms. While he hasn’t worked here long, he’s familiar with many of the horses.

“I’ve worked on a lot of them at other barns 2 years ago,” Morris says. “We’ve only been here a handful of times. We’re coming here kind of fresh.”

Silvio Domingues Da Silva, Prestige’s trainer, makes it easy for Morris.

“Silvio just wants us to shoe them — keep them plain and legal,” he says. “Everything is straightforward. He just wants to ride his horses. He doesn’t want any witchcraft. He just wants them sound.”

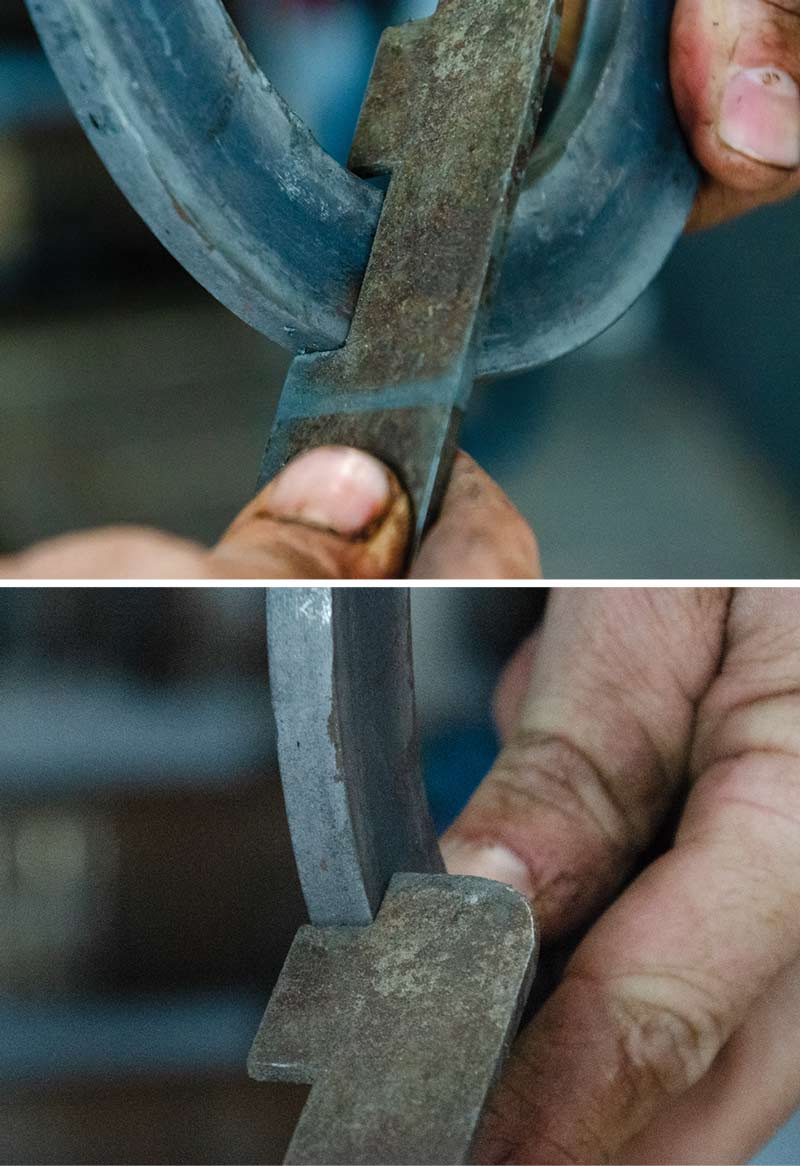

Arabian and Half-Arabian show horses have strict shoeing rules. The padded shoeing packages limit the stock to 1 1/8 inches x 3/8 of an inch.

“They have a gauge that they run around the shoe that’s 1 1/8 inches wide,” Morris explains. “It has a little notch for 3/8 of an inch to make sure we’re not over stock.”

Purebred Arabians cannot exceed a measurement of 4 ¾ inches from the hairline to the ground, while half Arabians must be 5 ¼ inches.

Many of the hind feet remain unshod to keep them lighter and freer.

“The hardest part is the potential for human error of where the hairline technically is,” he says. “We all know where it is, but hair doesn’t really start in a straight line. My interpretation of where I should measure from is probably going to be different than yours.”

The packages add length, which in turn enhances the horses’ natural motion. When these horses trot, the English horses are generally above level. The Country horses, hunters, and Western pleasure horses are lower, depending on the discipline and don’t trot as high as the English horses.

“The more length the foot has, the higher they’ll trot or the fancier they’ll look,” Morris explains. “Not on all of them, though. Sometimes when you add too much length to them, they kind of shut down. It’s the same thing with weight. The more weight you technically add, the fancier they get, until they get too heavy. If we were to shorten the feet and put the horse in a plate, then its knee wouldn’t go up as high. If you have a horse that stretches flat out in front of itself, you might get a little more knee by adding a wedge or rocking the toe. When you have a horse with a ton of knee and you pull the wedge out, it will generally travel a little flatter.”

Although Arabian packages are significantly smaller, it’s not uncommon for some outside of this breed to confuse it with another breed and their disciplines.

“We kind of have a black eye because of the Tennessee Walkers and the racking horses,” Morris says. “What people forget is these horses trot for a living. They significantly vet the horses. We can’t add foreign objects. They keep these Arabs pretty true, even though we do put toe weights on them.”

The difference between a toe weight and a plate is only a couple of ounces, he says.

“In a toe-weight package — with nice thick leather, with or without a wedge — we can reduce the leverage even more than we ever can in a plate,” Morris says. “I can rock the shoe up into the leather, grind off the leather and break the toe way back. Essentially, we’re just lifting the withers. Horses have a tendency to pull against weight, and the shoes that we’re putting on them really aren’t heavy.”

Purebred Arabians cannot exceed 4 ¾ inches from the hairline to the ground.

Hurry Up and Wait

After setting up Morris’ customized Bloomer Trailer and the shoeing area, Moana Kramer, who works at Prestige Farms, brings in the first horse of the day. Kramer will hold the horses for Morris and Wenham.

“We were here 2 weeks ago and did his feet,” Morris recalls. “I was really happy with his foot quality. They were not as nasty and split up. Within 3 hours, Moana sends me a picture and he’s pulled a shoe.”

The good news is that when the package came off, hoof wall didn’t go with it. The bad news is the horn is brittle and crumbly. Morris is concerned that the wall might not be strong enough for the nails to hold the package securely. Morris picks up the horse’s right front foot and places it on a polyethylene cutting board to ensure a flat surface for measuring the hoof.

“He’s purebred length because he was short when we first did him,” Morris says as he moves to the left front to repeat the task. “He’s a half-Arab. He’s at 4 inches, so he’s a solid of an inch shorter than legal. He has pretty poor feet, so you don’t want to leave him super long.”

Grabbing a tube of Equilox tan, Morris takes a couple of pulls on the trigger on the dispenser and squirts the adhesive into a paper cup. After mixing it, he applies it to the nail holes.

“We have to keep him together,” Morris says. “The nail holes were gapers. If you try to reach in for one, you could wind up splitting more wall. I’m just going to fill the holes. It might keep it from coming apart. It’s my favorite nail filler. The stuff doesn’t come out. It stays waterproof. Maybe it will keep the nails from lifting up.”

While waiting for the adhesive to set, Morris retreats to his trailer and retrieves a pair of bands. Since the horse will be going to Tulsa, Morris doesn’t want to take a chance on the shoe loosening. Applying a band to each package will provide some extra peace of mind.

While Morris builds the package, Wenham bevels the nail holes.

“Hurry up and wait,” he says as drills holes in the package with a Milwaukee nut driver to secure the bands. “I want these horses to stay together and not be pulled apart when they’re in Tulsa.”

After the adhesive dries, Wenham lightly rasps the bottom of the hoof wall to remove it from the package. She trades it for a half-round rasp to smooth the adhesive on the hoof wall, followed by a sanding sponge. Wenham finishes up the foot with a 120-grit sandbox.

Armed with the bands, Wiss M5 tin snips and the nut driver, Morris follows Wenham and applies the bands. He quickly tightens the band with the nut driver, then trims the excess band close to the nut.

Staying on Schedule

The horses on Morris’ roster typically have a 5- or 6-week shoeing cycle; however, there are exceptions. To comply with the rigid shoeing rules at competition, he must adjust some cycles to ensure compliance. Bravo, a gelding that competes in Arabian Country English Pleasure Division, is one such horse.

“We knew he’d be long because Bravo is one of those that needed to be done a couple of weeks ago,” Morris says after measuring his feet. “If he was done earlier, he could have been too long at the show. Or the longer the shoes are on, the looser they become. We want them nice and tight, and as close to being legal as we can during the show.”

Although Bravo competes well — winning and placing in regional driving contests — his front legs tend to interfere with each other. While shoeing is improving the number of occurrences, it persists.

“He’s not pretty on the front end when we do him,” Morris says. “He swings his left front and hits his right front. He wasn’t doing it badly, but it was enough to hear it. He’s a driving horse, so we have sort of a pseudo side weight on him. We are setting it to the outside so he wouldn’t hit. It’s not as bad, but we also have a little bit of weight on the lateral.”

After Morris measures both feet and pulls the front packages, he kneels off to the side to take them apart. Wenham places Bravo’s right front foot on a hoof stand and dresses the horn.

It’s easy to be successful when you have good help …

“We got our money’s worth out of these pads,” he says while nipping the nails that hold the package together. “Lill, there’s brand new sandpaper on the silver one. He’s going to Tulsa, so we’re sanding him.”

Holding Bravo’s right front foot between his legs, Morris pulls a regular screwdriver from his apron and begins digging out the old hoof packing.

“My fancy hoof pick,” he says with a chuckle. “It’s been worn out over years of use. I bought it 15 years ago or something for about $8. Hoof picks hurt my wrist, and a regular flat screwdriver allows me to get more leverage. I tried switching back and I couldn’t stand it.”

Morris grabs a hoof knife from his apron pocket and begins his trim.

“I have a measurement in mind,” he says. “He’s 3/8 of an inch over legal, so I know I’m taking at least 3/8 off of it. Usually, purebreds with a 3/8 shoe and a Keystone leather pad wind up being trimmed down to about 3 ¾ inches. He’s pretty even. He’s just over 5/8, that way he has room to grow over the next 3 or 4 weeks. If we were at the show, I’d cut off exactly what he needs.”

Morris makes his own hoof knives because he prefers a narrower, shorter blade when maneuvering around the sole.

“Arabians grow a ton of sole, so I probably use a knife more than most,” he says. “This horse is going to be trimmed down to 3 ¾ inches and stays at 4 1/8 with the package, which will give it 1/8 of an inch to grow before it is at max length. I try to leave healthy sole. If it doesn’t need to go, then I don’t want to take it. We’ll leave half-Arabs at 4 ¼ and we’re leaving dead sole because it holds everything together. If it comes out, it’s dental impression time. So, we try to leave as much sole as we can. We’re trying to get good concavity and a good healthy foot.”

Morris applies a 50/50 blend of Thrush Buster and denatured alcohol to Bravo’s central sulcus, commissures and nail holes to ward off opportunistic bacteria that might find their way under the impending shoeing package. When the front feet are prepared for the packages, Morris and Wenham return to the trailer to work on the package. They will reset both shoes but as Morris indicated earlier, the pads have arrived at their expiration date.

LEARN MORE

Gain more insight on shoeing Arabians and high-low horses at AmericanFarriers.com/1222

Selecting a No. 4 Iron-Craft pad, Morris places a 3/8 x 1 inch even weight with the heels over the wedge. He slides the toe toward the edge of the pad so that it overlaps, but covers the inside web. Morris approaches one of two Jet drill presses where he passes the bit through the shoe’s nail holes. After passing the pad through the rivets, Morris removes most of the wedge at the heels with a band saw. A Keystone leather pad is attached over the wedge pad and the package is riveted together. Morris runs the edges of the package over a belt sander to remove excess materials for a cleaner appearance.

Morris hands the first package to Wenham, who turns to the second drill press and widens the nail holes in the pads with the bit.

“She’s beveling the nail holes all the way through,” Morris explains, “so I can pitch the nails anyway that I want.”

When the packages are completed, Morris and Wenham return to nail up Bravo.

“We set him pretty tight on the inside and full on the outside,” Morris says. “Tighter than we want on the inside, otherwise, he’ll hit himself. This is one of those horses that you take a picture of and other farriers say, ‘Why did you do that?’ Well, there’s a little back story here.”

Many of the horses at Prestige Farms are barefoot behind, and Bravo is no exception.

“Some trainers like the horse a little lighter and freer in the hind end,” he explains. “A little more weight there and it almost forces their hind end under them, which some need. It also depends on how sound they are, how they’re built or if they need support. Silvio likes to keep it as simple as possible. If the horse can go barefoot on the hinds, it will.”

The Arabian horse shows have a gauge that they run around the shoe that’s 1 inches wide (left) and of an inch (right) to ensure the shoe is legal.

The shoeing package consists of a shoe, plastic wedge and leather pad.

Lateral Support

After returning Bravo to his stall, Kramer leads Sydney to the shoeing area. Like Bravo, Sydney is also overdue because the timing of his typical shoeing cycle conflicts with the upcoming show.

“This is going to be an interesting measurement,” Morris says. “He’s close to

3 5/8, so he’s up there a little bit.”

Morris pulls the package and gives way to Wenham, who brings the foot forward onto the peg and begins dressing the hoof wall. Off to the side, Morris removes the nails from the package, which consists of a toe-clipped Anvil Brand toe-weight blank, sole pack, leather pad, and plastic wedge pad.

“I mark out and punch the blanks,” he says. “It’s either that or I’m drawing these things out. A lot of guys do it, but it takes some time. I’d rather not toe clip them, but Sydney is carrying 15 inches of stock on a 12-inch foot and then a big wedge. That’s when we start doing it. Otherwise, the package starts sliding back pretty easily. Once the shoe is built, we just use the MiG to weld it on.”

Morris returns to his trailer to clean up the package at the belt sander. The package remains in good shape, so he’ll reset it.

“The leather will stretch out sometimes,” he says. “A lot of guys don’t like to reset them. I don’t have any problems with it, unless they’re in bad shape. They get so many baths and just with the pressure, the pads spread out under the foot.”

With the packages completed, Morris returns to Sydney for the trim. Grabbing a loose piece of frog, it separates easily from the foot.

“Those are my favorite frogs,” he says. “I’m going to leave as much of the sole as I can. He’s about 4 5/8. I’ll cut him down to just under 4 1/8. We’re going to need some dental impression material.”

After completing his trim, Morris measures the dorsal hoof wall, then switches out the ruler for a hoof gauge.

“I try not to fight the angles too much,” he says. “More than anything, I just want to match them as close as I can. His foot has gotten better. He was really crooked when he showed up. When there wasn’t enough foot taken off the toe, he was crushing the lateral heel. In a perfect world, we would have done him a couple weeks ago, but this world’s not perfect.”

Every breed has a different set of problems, Morris points out. While navicular isn’t heard frequently among Arabians, they have their fair share of high-low occurrences.

“Pretty much every horse that we’ll see today is going to have high-low,” he says. “I would say 90% of the time, the front right is the high foot and the front left is the low. It’s not all the time, but the majority of the time.”

When shoeing an Arabian with high-low, Morris pays particular attention to the height of the shoulders.

“You have to look at the body a bit more,” he says. “Generally, when you have an upright foot, the shoulder is a little bit lower. A lot of that might be muscle mass because there’s more muscle on the left. A lot of these horses are going to struggle on the second direction. They’re going to be on that right lead, so they might have a tendency to break lead with an amateur on their back. They’re not going to want to use that foot as well as their low foot. Arabians are trotting, so they’re judging them on an even trot, as well as a lot of other things. We usually have to add a little bit to that foot to keep it even with the other one.”

Lillian Wenham bevels the nail holes so Zach Morris can pitch the nails.

Sydney is high-low, but he’s the exception to the rule — his upright foot is his left.

“He was about 4 1/8 on his right and I left him about 1/8 longer on his left to make up for the upright foot,” Morris says. “He was within a degree when I was done with him, which is what we shoot for. In a perfect world, I could get him under on the upright, but it’s not going to happen.”

Morris nails the packages to Sydney’s front feet and moves on to the hinds.

“I measure the hind feet, too,” he says. “I measure everything. Hinds still have the same rule, but we don’t leave them long. I match them in length, otherwise they won’t travel evenly. Everything gets measured.”

While Mo and Bravo are barefoot behind, Sydney is shod with St. Croix Extras. Morris finds that most Arabians and half-Arabians stand cow hocked. They tend to grow more hoof wall on the medial side, which can lead to crushed lateral heels.

“The lateral heel was really crushed last time,” he says. “It’s looking a little better now. The Extra is a standard pattern; it’s neither a front nor a hind. It’s punched coarse, which makes it good for when you’re doing a plate and a pad.”

Morris added a trailer to the lateral heel to provide a little more support. He applies Hawthorne sole pack to the bottom of the foot before nailing the package onto the foot.

“I put a trailer on most of these horses,” he says. “It’s no different than you having a wide heel on your shoe. It just gives you a wider base. When these horses drive off their hinds while in the bridle, most horses do 60-65% of the weight in front. Flip that around because the motor is in the hind end. They need more support in their hinds because they’re using it so much more. We’re splitting hairs at this point, but if there’s anything we can do to just give them a wider base of support, I think we should do it.”

Morris punches Anvil Brand blanks and rivets them to the Iron-Craft wedge pad.

Growing More Lateral Toe

After finishing Sydney, Morris sets his sights on an unnamed purebred Arabian stud that the farm recently welcomed.

“You can see how much the horse grows lateral toe,” he says while holding the right front foot between his legs. “We have some foot. He measures 4 ¼. I’ll trim this foot down to about 5/8. He has a hard sole and there will be a little heel coming off, the lateral, especially.”

The stud arrived with a toe-weight shoe and a pad, but Morris will shoe him with a new Anvil Brand rockered blank, leather pad and wedge.

“I think it will be better with a wedge since the horse trimmed out pretty low,” he says. “He’s a little more upright on his left, so I’ll probably rock his left less than his right. His trim didn’t quite come out the way I wanted. Even though it’s higher, I’m OK with that. That sounds odd, but I can’t get him as close as I want in the trim. I knew he was going to end up moving short on his left, so I’d like to keep it down just a tiny bit. Anything we can do helps.”

Morris moves onto the hinds after nailing the new packages on the front feet.

“There’s not a lot of concavity here,” he says after trimming the foot. “His angles are within a couple of degrees. I’ll probably get him better next time on the trim. He’s still a little low even after putting the wedge on.”

Such is the life of an Arabian show horse shoer — keeping the mounts sound while ensuring they fall within the legal measurements, matching angles as closely as possible, all while navigating high-low and cow-hocked conformations.

Post a comment

Report Abusive Comment