American Farriers Journal

American Farriers Journal is the “hands-on” magazine for professional farriers, equine veterinarians and horse care product and service buyers.

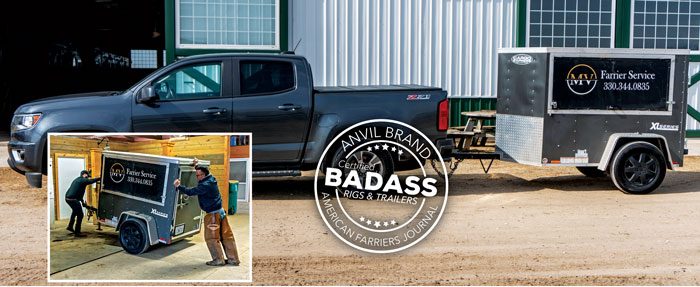

Miguel Vasquez doesn’t pretend to be a professional fabricator. Although it isn’t his career, the Grand Rapids, Mich., farrier enjoys learning the skill set through taking on tough projects. When it came time to launch his full-time shoeing business, he found a challenging fabrication project in building a new trailer.

Vasquez’s inspiration for building a trailer was simple: saving money. He didn’t see the point in taking on a large expense of a manufactured body or trailer after graduating from Oklahoma Horseshoeing School.

“When I left school, I didn’t want to spend a lot of money,” he says. “I had many thoughts on how to build my business, and fabricating my trailer was part of that.”

Although he graduated in 2020, Vasquez wasn’t new to the trade. His first began as a Paso Fino trainer in Puerto Rico. Fascinated by shoeing, he eventually learned how to trim and shoe his horses. Vasquez realized he enjoyed the problem solving presented by farriery more so than training horses and made the career change. He felt the Purcell, Okla., school would improve his knowledge and ability.

Based in Grand Rapids, Mich., Vasquez has not only built his trailer, but also a solid business. He works on a variety of horses, including jumpers, dressage and barrel racers. He also shoes for a couple of Paso Fino accounts, including one about 300 miles away in Illinois. Otherwise, most of his work is in Western Michigan.

Vasquez visits this Illinois Paso Fino barn about…