BADASS

RIGS & TRAILERS

In 2021, we will showcase standout rigs and trailers in the magazine and on AmericanFarriers.com. To see a video showcasing this rig and on future trucks and trailers, visit AmericanFarriers.com/rigs.

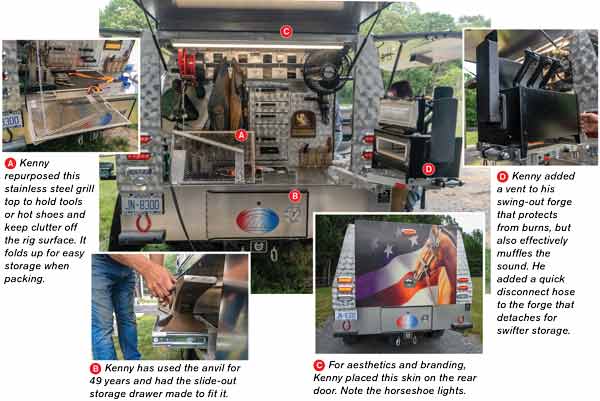

The December 1990 American Farriers Journal featured an article by Martin Kenny showing how he made his 1987 Ford F-350 custom walk-in rig — a rarity at the time. Over the years, other rigs came and went, including a stripped-down minimalist approach. Earlier this year — his 49th year of shoeing — Kenny picked up a new truck body from Stonewell Bodies. Although the Carthage, N.C., farrier isn’t ready to hang up his apron, he realizes this is likely his last rig. Many learned lessons of efficiency gained over the decades influenced its design.

No Time Wasted at the Barn

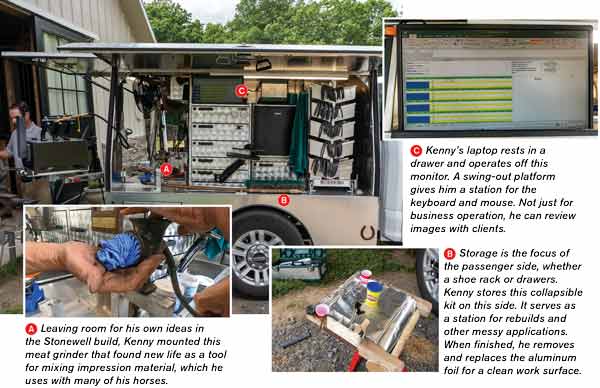

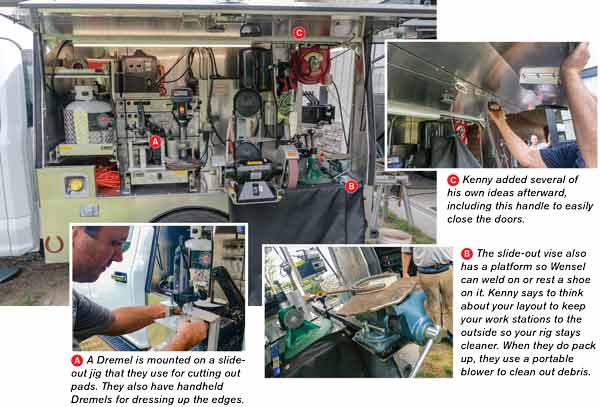

Kenny’s practice covers the Mid-Atlantic, as well as several other states, so he puts on plenty of miles each year. His practice works with sport horses, therapeutic cases, minis, driving horses — a diverse book. Kenny often works with Broadway, N.C., farrier Ryan Wensel. The travel and work with an associate influenced the layout for this rig.

Kenny designed the rig so it can carry the tools and supplies he needs for multiple-state travel. For example, there are two propane tanks on the driver’s side for his forge and for his brazing torch. If the current tank is empty, Kenny can switch to the other tank by turning two valves. He doesn’t want to run out of propane while on the road and waste time hunting for a supplier.

Although he can carry the inventory for multiple horses doesn’t mean Kenny hauls a supply shop load of inventory.

“Carrying shoes that you know you won’t need costs you,” he says. “My system is to restock every night at home. I don’t need 20 pairs of #3 hinds. Instead, I carry four pairs of everything I typically use. If I’m going to be away, I can prepare for that. At home, I look at the slide out shoe rack and replace what is missing.”

Kenny uses that time at home to prepare for the next day. He keeps four hoof knives for the day that he sharpens each night. Before any shoe goes on his truck, he grinds the heels.

“I’m going to have to do that, so by doing it at home, I save time at the barn,” he adds.

Design Based on Workflow

Overall, Kenny says he worked to make sure the layout can handle two people working together without interruption. The passenger’s side is storage, with the shoes being the only thing used with most of his horses. The rear is the work station with forge and anvil. Kenny looks at the driver’s side as the assembly area, where Wensel can cut pads, weld inserts or anything focused on construction without being interrupted. Unhampered workflow is all part of Kenny’s commitment to efficiency.

“A rig layout should reflect how the farrier works with the horse,” he says. “Before you get a new rig, think about what you use the most and what you take out the most often. Analyze how you can minimize steps working around it. The key to any business is to make money. And time is money, so you can’t waste time when you are at a stop. You have to be a stickler for efficiency.”

Click to enlarge images.

Post a comment

Report Abusive Comment