Like many farriers, Rick Padgett of Vale, Ore., has accumulated quite a collection of worn-out rasps. Thanks to his son, he now has a use for them, according to the Malheur Enterprise.

Two years ago, Padgett’s son wanted to make a present for his uncle.

“It was during the Snowmaggedon, I think,” Padgett says. “My oldest son, who is now 13 years old, … saw that you can make a knife out of a file.”

His son noticed that Padgett had many horseshoe rasps lying around. The pair learned how to make knives from those spare rasps by watching YouTube videos.

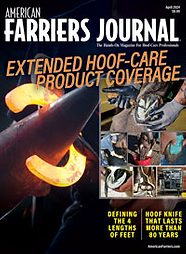

Padgett now makes knives for those who want to buy them, but he doesn’t sell knives regularly. Because his horseshoeing business is his main source of income, knife-making is limited to the winter months when his hoof-care practice slows down. Each knife takes 10 to 12 hours to make. Everything is done by hand, and there is a great deal of sanding required to complete each knife.

Padgett’s background in horseshoeing and blacksmithing helps him craft knives. After attending the Sierra Horseshoeing School in Bishop, Calif., he apprenticed under Terry Miffis for about a year before settling with his wife in Treasure Valley, Ore., where half of his relatives lived. They had their first daughter, and he needed to make money. Horseshoeing allowed him to do just that.

“This is where I ended up,” Padgett says. “And I like it. Being self-employed in this type of job enables you to let the kids ride in the truck with you. No babysitting or daycare required.”

Today, Padgett shoes horses for local horsemen and for nationally prominent trainers who travel for major races and rodeos. Knife-making will remain a well-loved side business and hobby he shares with his son. However, it’s something that he’d be willing to expand if he were able to get “all the fancy equipment."

Post a comment

Report Abusive Comment