When driving across several states to shoe horses, a farrier requires a reliable truck. Shelbyville, Ky., farrier Paul Human has counted on a 2005 Chevrolet C5500, which has logged more than 300,000 miles traveling across the seven states his clients reside. Because his practice combines traveling long distances and shoeing gaited horses, Human’s truck body also must fit his business.

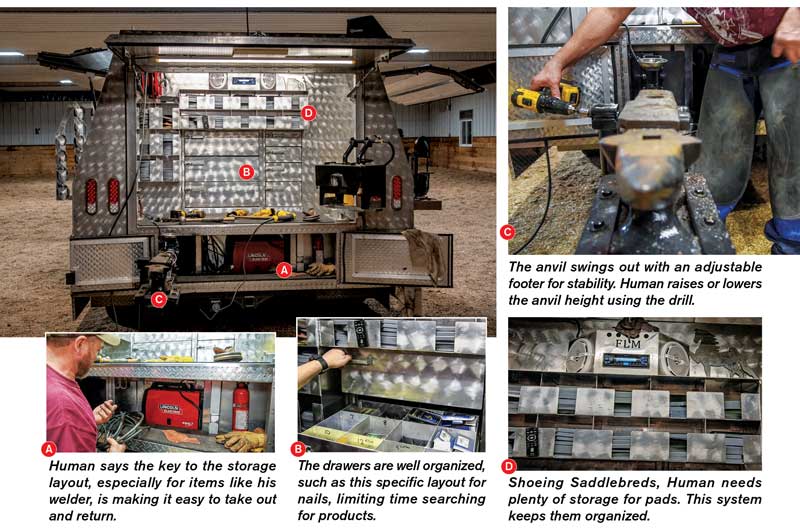

“There are usually three of us working, so we have to work together efficiently,” says Human. “We also make sure we have everything we need so we don't waste time getting supplies.”

Coming from South Africa, Human started shoeing in the United States about 25 years ago. He spent 9 of those working for Simpsonville, Ky., farrier Bud Willimon. He says no money in the world can replace the knowledge and experience Willimon has to share. These lessons are more critical, says Human, because the discipline isn’t as well documented as others.

He credits Willimon not just for the lessons on shoeing gaited horses, but also for instilling business sense. That isn’t only understanding the dollars and cents of the business or how to operate a multi-farrier practice, but additionally working with and moving around horses.

Human sees his shoeing rig as one of the many tools supporting his goal of preserving his body and aiding in the longevity of his career. For example, his crew uses DeWalt orbital polishers with 60-grit disks to finish feet. He also uses them to clean the foot while trimming, with what he believes is saving him time with the hoof knife and being under the horse.

“This is such a brutal job, any time you can override it adds longevity to your career,” he reasons. “Many farriers don’t realize how lucky we are to have access to the technology and tools. I’m trying to eliminate a step here or there. Using the sander with a horse saved me 10 minutes being bent over. It's about self-preservation.”

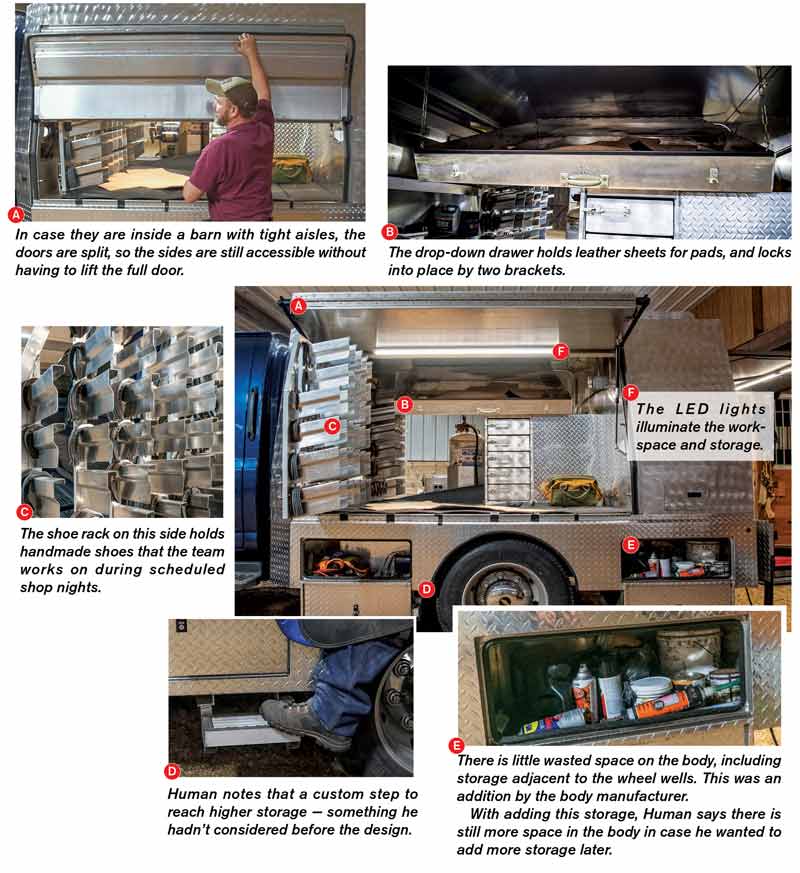

With the packages required for shoeing Saddlebreds, Human’s rig needs to have storage that is easily accessible. He adds that it should be visual as well. Time spent digging around for products or hunting for a particular shoe reduces efficiency.

New Shoeing Body

In May 2020, Human bought a new shoeing body, working with Finger Lakes Custom Manufacturing on the design. He came in with his own ideas, but says the rig manufacturer aided by providing ideas for improving the volume and efficiency of storage. Without that input, he would have missed storage added to areas he thinks of as wasted space, such as behind the shoeing racks. If you are in the market, Human says to tell the manufacturer what your most important goals are, and let them bring their expertise to the table.

With how he and his crew works around the rig, Human feels he has a truck body that will last the remainder of his career

“My rig is a versatile unit and can carry everything I need. It is self-sufficient because I can carry everything I need and get to it easy. Although I shoe Saddlebreds, I could shoe any discipline that I want off this unit. The sky is the limit on what you can order.”

Post a comment

Report Abusive Comment