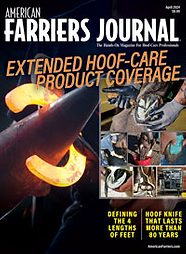

Pictured Above: Travis Koons takes a minimalist approach to therapeutic cases, focusing on proper trimming and fit. “It’s not so often the therapeutic device that helps the horse,” he says, “but good, solid horseshoeing helps the horse the most.”

“You don’t want to shoe lames horses, trust me.”

Bob Marshall tried to warn the confident young farrier, but the then 18-year-old Travis Koons had made up his mind. The Hemet, Calif., youngster had printed business cards, announcing that his farrier practice specializes in pathological, remedial and corrective horseshoeing.

“Why would you ever put that on your business card?” the legendary shoer asked him forcefully. “You don’t want to shoe lame horses!”

Farrier Takeaways

- Good, solid, basic horseshoeing helps the horse more in therapeutic situations.

- Determining the shoeing schedule for your clients will help prevent lame horses.

- Just remove what’s necessary for hygiene, balance and integrity when trimming feet.

- Concave mimics the horse’s foot in the way that it functions on the ground.

“Yeah, I do, Bob,” Koons told him. “I can charge more money.”

“No, you’ll get those old chronic horses sound and then you’re a hero,” Marshall told him. “But the minute they go lame again, you’re a zero. You’ll be getting calls in the middle of the night. You don’t want to do this.”

Koons was sure that this was the right path for him and carried on. It didn’t take long, though, for Koons to realize that the Hall Of Fame farrier knew a thing or two about what he was

talking about.

“It took a couple of years, but I realized Bob was right on the money,” Koons says, pulling his 2012 Dodge Ram 2500 through the gate of a boarding and rehabilitation ranch on a warm November day of “Shoeing For A Living.” “So, I’ve done my best to avoid chronic lameness cases over the years. I’d rather just shoe performance horses.”

This isn’t a typical client, though. Koons has been shoeing for Emalee Tomoni since she was just 5 years old. Now, more than 20 years later, Tomoni operates Talley Meadows, a successful boarding and rehabilitation facility.

“Now this account has evolved into a layup and rehab place,” says Koons, whose practice consists mostly of dressage and jumping horses. “I’m doing a lot of therapeutic-type work. Typically what I have learned over my career is that it’s not so often the therapeutic device that helps the horse but good, solid, basic horseshoeing — proper trimming, proper fit that helps the horse the most. So I go at my therapeutic work with an extremely minimalist approach.”

Managing Client Expectations

Handling the client’s outlook on their horse’s recovery often can be as much work, if not more, than actually helping the horse.

“That’s a big aspect of our job,” he says. “I’ve learned that the best clients are the ones who you actually take the time to educate and inform. Sometimes it takes a lot more time than I want, and a lot more time than I have. In the end, it reciprocates and becomes worth the time that I spent. It actually costs me less time down the road.”

It’s important to get as much information as possible from the client.

“Asking questions helps a lot,” Koons says. “Find out about the horse’s history of lameness and soundness; what it’s done; how old it is; and what they know about different injuries the horse might have had, even before they owned it. That history is oftentimes helpful.”

PHOTO GALLERY:

Farriers At Work: Travis Koons

Communicating with clients in therapeutic cases means candor.

“It’s our responsibility to be honest,” Koons says. “I’ve always found that it’s just best to be as brutally honest as possible. I don’t candy-coat anything.”

Yet, it also involves thinking the conversation through.

“I come up with a game plan before I start talking,” he explains. “I’ll take my time to look at the horse. While I’m evaluating the conformation, hoof quality and issues, I’m going through that in my head. I might call out a few things about the conformation to the owner. As I’m explaining these things, I’ll be rehearsing in my head what I’m ultimately going to say about what needs to be done and what the options are.”

When options are limited by the client’s pocketbook, Koons will take the time to find some alternatives that are more cost effective.

“I’ll explain more specific things that we can do for that particular condition,” he says. “While I’m doing that, I’ll explain how much these different shoes, techniques, pads or whatever might cost. Ultimately, they are the ones who have to pay the bill, so you need to give them options for their own budget.”

Even the best teachers need willing students, though.

“You’re still going to have those clients who have a horse with ringbone and expect it to be sound for the rest of its life,” Koons says. “If their expectations don’t marry with mine and they let me go because they want someone with a better attitude, then it’s all good.”

Koons found significant hoof wall separation after pulling Bijou’s shoe. After trimming about three-quarters of the hoof wall, the separation wasn’t as serious.

Avoiding Therapeutic Cases

To limit the number of therapeutic cases he has in his book, Koons takes control of the horses’ feet.

“I want to work with people who know and respect that I’m the hoof expert, not the vet,” he says. “That’s something I try to show them, rather than tell them. My goal as their farrier is to make it to where they don’t ever have to think about their horses’ feet.”

Koons accomplishes this by maintaining their hoof-care schedules, rather than the client calling him when they are due.

“I figure out when the horses need to be done,” he says. “I like 6- or 7-week cycles, depending on the individual horse. They don’t have to think about when they’re due. They don’t have to think about the wall chipping or breaking. They don’t have to look at hooves that aren’t right.

“A facility like this is great, because I have some horses at 6 weeks, some at 7, some at 8. Emalee is looking after about 60-head of horses, so if she has to think about everything else these horses need and their feet, it’s going to get overwhelming.”

Taking on a new client can be taxing initially.

“I’m used to doing things my way and being in charge of the feet and shoeing,” says Koons, who’s been shoeing for nearly 30 years. “They’re used to micromanaging every little aspect of their horse. They think they like that, but once they get used to letting go of the reins, they realize that I’m going to show up and I’m going to take care of the horse before it becomes an issue.”

It usually takes two or three shoeing cycles before his new client realizes they have nothing to worry about.

“I can’t tell you how many people tell me that their horses need to be done a minimum of 4 or 5 weeks because they’re show horses,” he says. “I explain my theories and that I like to have more foot. If they can go 6 weeks, I prefer that.”

If the potential client resists his 6-week schedule, Koons agrees to a compromise.

“I tell them, ‘OK, go ahead and write me down in your book and call me when you think they need to be done,’” he says. “I had one client text me at 6 weeks and ask whether it’s been 5 weeks yet. I told her no, we’re actually in the sixth week. ‘Are you kidding me? I’m not used to my shoes being tight and the feet not growing over the shoes.’”

LEARN MORE

Here are more ways to gain hoof-care insight from Travis Koons, including:

- Reading, “10 More Tips For Modifying Keg Shoes.”

- Reading, “Straight-Up Advice For Fullering.”

- View a photo gallery and watch video from the day with Koons.

Access this content by visiting

americanfarriers.com/0318

A Typical Case

After opening up his Stonewell trailer and setting up, a groom brings Max to the shoeing area. Koons asks the groom to stick around and hold the big bay rather than use the cross-ties.

“The last time I shod this horse, it was scary,” he says, noting this is only the second time he has shod this horse. “I was worried about him feeling the nailing because his hoof was in such poor condition. It was weak, soft and crumbly. I was already calling him a gentle giant, because he stood perfectly through the trim. It was the first nail, so I put it in the most solid place I could find, and he exploded on the first tap of the nail and about flipped over. It was quite the reaction to a tap of the hammer. There’s no way it went in deep enough with one tap. He was anticipating it.”

In situations in which a horse might be anticipating a bad nailing experience, Koons tries to be gentle with the hammer.

“I watch a lot of young, inexperienced farriers who are hitting the nails as hard as they can,” he says. “You can hear the hammer ring with every blow. As I start nailing, I’m making sure it feels solid and also feeling for the horse to have any sort of reaction toward it before I drive the nail home.”

Koons also will drive just enough nails to hold the shoe in place and then switch to another foot.

Max arrived at the facility lame with a possible soft tissue injury. The shoe was set far back in the toe, which was left long. The shoe wasn’t covering the quarters and there was a lot of heel hanging out of the back.

The horse’s vet anticipated that a month of rest would do the trick. No shoes were necessary. After a month, there was no change.

“His feet were falling apart,” Koons says as he cleans out the left front foot. “This foot had massive thrush. The right front was still lame. I was finally given the go-ahead to shoe him.”

In just 2 weeks, Max showed dramatic improvement with a shoeing package consisting of concave shoes, a Castle Plastics Cushion Frog Pad, impression material impregnated with copper sulfate crystals that covered two-thirds of the foot and RATE Hoof Packing in the toe.

“He was almost completely sound,” Koons says.

Now at 7 weeks, Max’s feet are much stronger despite being on irrigated grass the whole time.

“That’s nice,” he says as pares the frog and sole. “That was all sensitive tissue last time. It’s solid.”

Koons puts Max’s foot down and retreats to his rig where he begins sharpening his hoof knife.

“I got ahead of myself,” he says. “I was thinking that since he’s been in a wet pasture that his feet would be pretty soft. The copper sulfate has kept the moisture at bay and kept his feet nice and tough.”

It’s quite the transformation from when Max first arrived.

“I guarantee that he did not come from a grass pasture,” Koons says. “He came from a box stall filled with pine shavings. He had no pads and his foot was like a sponge. They were marshmallow consistency. Now he’s spent 7 weeks in pads on grass and his feet are twice as hard as they were. It’s kind of the opposite of what you’d expect.”

Toe clips allow a more natural, accurate fit and allow a natural hoof function, Koons says.

Trimming For Integrity

When starting out as a 16-year-old, Koons had the fortune to be the son of a farrier, Keith Koons of Winchester, Calif.

“My Dad taught me that horsemanship is hands down one of the most important aspects of horseshoeing,” he says of his father, who has been practicing hoof care for nearly 50 years. “I’ve been very fortunate to have him as my mentor because he is the finest horseman I’ve seen.”

That relationship has key in helping the younger Koons with navigating twists and turns in the industry. As a teen, Koons was understandably struggling with the notion of how much foot to remove.

“He said, ‘Just knock out all the dead material and trim off whatever’s sticking up above it,’” Koons recalls with a laugh. “He pretty much hit the nail on the head. I just remove what’s necessary for hygiene, balance and integrity.”

It involves using a careful eye and planning for what can be removed, he says.

“Oftentimes, you find that you need to leave more than you thought just from your initial observations,” Koons says. “I try to let the horse tell me what it wants. I try to leave some integrity where the sole is nice and firm, and there’s enough height to the hoof wall to where you still have a bit of an arch to the foot and some cup to the sole.”

His trimming style has helped him sleep at night.

“I can hardly think of a time when I’ve lain in bed at night unable to sleep thinking that I wish I had taken more foot off of that one horse today,” Koons says. “There have been a whole lot of nights when I’ve lain there thinking, ‘Man, I got pretty aggressive on that second horse today. I sure hope she’s going to be OK.’”

Max has a severe medio-lateral balance, which is indicative of poor breeding practices, Koons says.

“One of the big issues that we face as farriers right now is poor animal husbandry,” he says. “I can’t tell you how many times I hear, ‘This mare went lame when she was 5, so we made her a broodmare.’ That’s terrible. It didn’t used to be that way. They only bred the best horses that stayed sound the longest. Conformation and hoof quality were always a factor, but now there’s little to no consideration for that.”

There seem to be two camps in relation to the trim — those who prefer trimming to the hoof-pastern axis (HPA) and those who favor medio-lateral balance.

“I find that medio-lateral balance is oftentimes achieving or getting as close as possible for the animal’s conformation,” Koons says, “and what makes a difference in its soundness.”

The shoer recalls trimming advice from another Hall Of Fame farrier.

“In regard to medio-lateral balance vs. HPA, Jim Keith said that there is so little movement medio-laterally that a horse can only compensate for a little bit of medio-lateral balance,” Koons says. “With the hoof-pastern, there is great range of motion in the fetlock, pastern joint and the coffin joint, so they can compensate for much more balance on that plane. So when trimming, I put a lot of emphasis in trying to get the foot balanced medio-laterally.”

It’s important to understand how Koons references balance.

The best clients are the ones you take the time to educate …

“Balance is a bit of a buzzword with how it’s used mostly,” he says. “It’s a term that’s thrown around loosely. I think it’s rather arrogant to say you can fix a horse’s balance. Jim summed it up very well when he said, ‘When I use the term balance, I’m thinking more of bringing things into equilibrium.’ I like to say that I’m getting the proportions as equal as possible.”

Koons moves on to Max’s right front, pulling the shoeing package.

“That frog is just as clean as can be under there,” he says. “It wasn’t as bad as the other foot, but there was a lot of thrush here the last time. That copper sulfate never ceases to amaze me.”

After dismantling the packages and adjusting the shoes at the anvil, Koons is ready to hot-fit the right front.

“I like to have a nice platform of hoof wall and white line for the shoe to sit on but not burn the sole,” he says. “It’s important to leave enough wall for your burn so you don’t have to come back and re-knife the sole. It does happen from time to time.”

Achieving the proper fit, Koons quenches the shoe, cleans it with a wire brush and rivets the pad back to the shoe.

“A well-built pad will last a long time if it fits the horse well,” he says. “If the foot had changed a lot in shape and I had to change the shape of the shoe, then I’d be getting new pads instead of forcing the horse into the old pads. Everything is about where it needs to be in terms of the shape of the shoe in relationship to the foot, and the pad’s in good shape. The rivets pulled out nice and clean. There’s really no sense in replacing the pad.”

Koons retrieves green and white impression material called Silputty 40, which is manufactured by Silpak. The two materials are necessary to create a chemical reaction so it will set. If just one is used, it will have the consistency of Play-Doh.

“I’ve never been a fan of the really soft impression materials,” he says as he mixes the two materials. “That very well might be because I live in a drier environment but I’ve found that most feet do quite well with this one, which sets up quite firm compared with most.”

Koons places one side of the impression material into a container of copper sulfate crystals, then places it on the pad. Returning to Max, he brushes dirt and debris from the sole and squirts powdered copper sulfate into the fissures in the frog. Koons places the impression material impregnated with copper sulfate over the frog, then manipulates it until the back two-thirds of the foot is covered. RATE Hoof Packing is then applied to the toe area of the sole before Koons puts the shoe in place and bumps it into place.

“Tapping that shoe back in the clip sockets is a good little warm up for him,” he says, referring to Max’s sensitivity to nailing. “His foot is nice and solid. I know right away that it will nail much easier. It’s going to be a more pleasant experience for both parties involved this time.”

Koons drives three nails in a staccato rhythm to keep the bay from anticipating the hammer blows.

“That’s a good time to load him up to help equalize the impression material,” he says after driving the third nail. “It gives him a mental break and the impression material gets a little time to settle.”

The temperature is in the upper 70s, which makes for a comfortable November day, but isn’t ideal for setting up impression material.

“When it’s 90 to 100 degrees, it will set up in minutes,” Koons says. “If I put the foot on the stand right now to clinch, it would just squirt out the back.”

After the impression material sets, Koons finishes up the front feet, and trims the hinds. Before sending the groom on his way with Max, Koons fills the nail holes with Plumber’s Putty.

“It’s mostly for aesthetics,” he says. “But I think you might get some degree of moisture prevention when they walk around in the dewy grass. Those nail holes are just collecting water. I think the Plumber’s Putty will at least keep the water from pooling in the old holes.”

Koons applies RATE Hoof Packing around the rim along the sole to prevent dirt and debris from collecting under the shoe. Dirt build-up can spring a branch and create white line separations.

No Support

The next horse — Bijou — is a bit of a mystery. This is the first time Koons has shod the horse. The show horse has egg bars on his front feet. While it’s not known why it needs egg bars, it appears that the heels have been rockered.

“What are you putting an egg bar on for?” Koons asks. “Typically support, right? If the hoof is not in contact with metal, how is it supportive?”

Although, the egg bar is not doing its job as it’s been applied, the owners wish to keep the horse in the same set-up since he’ll be going back to work soon.

After pulling the shoes, Koons finds that there’s some hoof wall separation in the hinds.

“It’s completely separated almost from heel to heel,” he says. “There’s a little bit of white line in the medial toe. Hopefully it’s not too deep.”

Koons takes out a tape measure to record the toe length.

“I like to check the toe length on new horses to see how long there are,” he says. “This foot is telling me that he has a whole lot of excess depth at the toe.”

After trimming the foot, it has been reduced from 4¼ to 3½ inches.

“It could go even shorter, but I don’t want to take it to an inch,” Koons says. “That’s a big change all at once. All of the hoof wall separations around the toe have trimmed up well.”

Koons retrieves two pieces of concave bar stock to forge hind shoes for Bijou.

“Concave is timeless, just like a George Strait song from the ’80s is timeless,” he says. “It’s every bit as popular today as it was then. That’s how concave is. It’s been used for several hundred years in one form or another.”

While Koons doesn’t use concave exclusively, it accounts for about 96% of the shoes that he applies.

“It’s my opinion and the opinion of a lot of the best horseshoers I know that concave is the best option for most feet,” he says as he works at the anvil. “It mimics a horse’s foot, not only in the way that it looks but in the way it functions on the ground. So many people think that it’s too much traction. It’s not too much traction, it’s adequate traction for what the horse needs.”

While medio-lateral balance is critical for the horse, Koons says that getting feet flat is equally important.

“I had made what I though was a really nice pair of roadsters at a contest that was being judged by Shayne Carter,” he says of the Hall Of Fame farrier from Utah. “On the initial inspection, they were in first place. They paired up great and had a great nail fit.”

As the day wore on, though, they kept moving down the table. After it was all said and done, Koons approached Carter and asked why they moved so far down from first.

“He flipped the shoe over and showed me that the bearing surfaces weren’t really level,” Koons recalls. “They weren’t far off, but they weren’t really flat. Then he showed me a pucker in the medial heel, right above the wedge on the bearing surface. It was a little hole. Shayne told me that horse has to stand on that for 6 or 7 weeks. He told me, ‘The least you can do is give it a nice flat bearing surface to stand on. That little hole is going to gather debris, which is going to tear up that horse’s heel as it expands and contracts.’

Koons uses concave for about 96% of the shoes he applies. “Concave is the best option for most feet,” he says. “It’s not too much traction, it’s adequate traction for what the horse needs.”

“I learned a valuable lesson at that contest. No matter how beautiful a shoe is on the ground surface, it’s the foot surface that really matters to the horse.”

The two-time American Farriers Team member and three-time World Championship Blacksmiths National Champion says forging a flat shoe is one of the most difficult tasks to achieve.

“It takes time,” Koons says. “You have to maintain it throughout the whole shoe-shaping process. The further you let it get from flat, the harder it is to get it back. It takes maintenance and it takes an eye. I’ve noticed a lot of people think their shoe is flat but they really can’t see where it’s not because they haven’t focused much on it. They haven’t developed an eye for it.”

The only way to develop an eye for it is to practice.

“It has to be part of your daily routine,” he says. “There are very few people I’ve ever seen who can just do subpar work in their everyday shoeing practice, and then turn it on at a contest and do high-quality, top-caliber work. It just takes a discipline of doing it on every single horse.”

The need to develop an eye for flatness is very much the same when trimming a foot that will remain unshod. However, a barefoot trim is different.

“You have to take into consideration what they’re going to do to that hoof,” Koons says. “Some people try to make a flat hoof wall plane, like they’re going to put a shoe on it, but the quarters won’t be strongly attached. As soon as that horse starts running around, it blows its quarters out. If you just dip them a little for strength, then you won’t have as much damage occur to the hoof.

“There are very few of them that I actually trim flat. I’d do more what I call level — medio-lateral — all that would be the same. Typically, though, I’ll ease the quarters out a little bit on a barefoot trim, depending on the horse and what the foot tells you. It’s not necessarily a four-point trim or anything like that, but just basically a trim for strength.”

After forging a pair of toe-clipped hind shoes, Koons takes them to the horse.

Proper trimming, proper fit helps the horse the most …

“Toe clips allow a more natural, accurate fit, and they allow a natural hoof function,” he says. “I almost guarantee this horse was cold-shod with clips. The clips weren’t burned in at all. They’re just hammered up against its foot. Once that occurs, they’re not a quarter clip or a side clip, they’re a quarter clamp or a side clamp.

“That causes a lot of distress within the hoof capsule. It causes the hoof capsule itself to morph in shape because it’s pinched in that area of the clamp. You’ll lose the natural arch of the foot and it becomes a big straight spot, and over time the hoof will actually begin to take on an hour-glass appearance.”

Each clip has its own specific functions.

“Quarter clips and side clips are used when you’re trying to stabilize a fracture or restrict hoof movement,” Koons explains. “If it’s just for the purpose of keeping the shoe secure and taking stress off nails, then a toe clip will do the job and still allow normal foot function 99% of the time.”

Koons cleans out the fissures in the bottom of Bijou’s feet, then applies copper sulfate dust and covers them with hoof packing.

“It only takes a few seconds on average,” he says.

After nailing on the shoe, Koons applies RATE Hoof Packing along the rim on the sole surface.

“It keeps dirt and debris from collecting under there and springing a shoe or creating white line separations,” he says. “I’ve also noticed that it keeps the white line soft enough to cut with a knife, even though the rest of the foot is hard and you can’t do that.”

Koons moves on to Bijou’s front feet and prepares to make a pair of concave bar shoes.

“I’ve had some guys ask me why I would take the time to make a bar shoe for a horse that I’ll never shoe again when I could nail on a keg shoe,” he says. “It’s just a matter of pride. Putting a keg shoe on this horse is not the best I can do for my skill set. It’s for the horse.

“Instead of compromising and being limited by a keg shoe, why not just build one right from the start for that horse’s hoof? To me this is fun.”

As he approaches Bijou to nail on the bar shoes, the number of influences within them is striking to Koons.

“One of the things I like most about horseshoeing is the tradition,” he says. “As I’m going through the process and techniques, I think of all the different people who taught me. In this shoe, there are things that I learned from Bob Marshall, Dallas Morgan, Roy Bloom, Craig Trnka, Shayne Carter, Jim Quick, Jim Keith, Austin Edens and Myron McLane. So many people shared their knowledge to give one person the ability to shoe a horse.”

Post a comment

Report Abusive Comment