When it’s time to replace your grinding belt, you’ll find a spectrum of colors await at the farrier supply shop or hardware store display. The hues and shades before you aren’t necessarily random.

In the course of manufacturing tools at Bloom Forge in Drummond, Wis., Roy Bloom has the opportunity to employ a number of grinding belts for various tasks — everything from aggressive grinding to polishing tools.

While you might not consume as many belts as Bloom, the colors can offer you some indication of what to expect from them.

“You’re going to see blues, reds, greens, browns — all kinds of colors,” says the International Horseshoeing Hall Of Fame member. “What are they?”

Blue. Generally, a blue belt consists of zirconia crystals.

“Zirconia is the hardest crystal in grinding belts,” Bloom explains. “It is used for super aggressive grinding.”

As such, if you’re not using it for this purpose, the belt simply won’t work properly for you.

Farrier Takeaways

A 40-grit belt is well suited for the aggressive nature of removing material from a horseshoe. A higher grit belt is used to polish farrier tools.

The finer the grit, the quicker the metal gets hot. Be sure to cool your heat-treated tools often to avoid removing the temper.

Generally, the color on the belt is a coolant that the manufacturer has sprayed on the belt.

The crystals on a grinding belt must be able to chip and break to maintain continuously sharp cutting edges. If the material you wish to grind isn’t capable of breaking the crystals, it will be unable to remove the metal.

“In order for a belt to last a period of time as it’s being used, the crystals on the belt have to be able to chip and break. That produces new facets and new cutting edges all the time. If the grinding that you’re doing is not capable of breaking those crystals, then it just smooths them off. It might feel sharp to your thumb or finger, but it won’t cut anything.”

If you’re planning on using it to work on tools, you might want to reconsider.

“It does not work very well for flat grinding, say on a forepunch or if you’re grinding your pritchel,” Bloom says. “Zirconia will just generate heat. If you’re going aggressively, say at the heels of a shoe when you’re really going to be digging in, now that’s what the belt is for. It’s aggressive grinding; you know you can break the crystals.”

Brown. The brown aluminum oxide belts have some pros and cons.

“This is probably the softest crystal,” he says. “These belts work, but they don’t last very long. Because of that softness, they break easily and wear out quickly. They don’t cost as much as the other belts on the market.”

Brown aluminum oxide belts work well, but because it contains soft crystals, they have a tendency to wear out relatively quick.

Orange and green. Man-made ceramic belts are either orange or green.

“Generally, the color becomes the coolant that the manufacturer has sprayed on the belt,” Bloom says. “The ceramics seem to certainly last longer than aluminum oxide.”

If you’re looking for an aggressive belt that has a long life, you might want to consider the Cubitron. Minnesota-based 3M touts that not only will there be fewer belt changes as a result of its ceramic mineral precision shaped grain (PSG), but it will offer greater performance.

“3M scientists precisely engineered the mineral to form uniform triangular-shaped grains that continually fracture into super-sharp points and edges that slice through the substrate, rather than gouging or ‘plowing’ like conventional abrasives,” according to 3M. “PSG creates a super-fast cut and lessens heat build-up in the work piece, reducing heat-related stress cracks and discoloration.”

In his experience, Bloom has found that the polyester cloth belt lives up to the hype.

“The Cubitron belt is an expensive little bugger, but it lasts forever,” he says. “I mean, it probably costs twice as much as what you’re used to paying for a belt, but I think it probably lasts more than twice as long, too. It’s a pretty good belt.”

Although expensive, the Cubitron polyester cloth belt resists wear longer than others on the market, Roy Bloom says.

Gray. When it’s time to finely polish a tool, the 3M Trizact aluminum oxide belt is used by a number of manufacturers of tools that you probably have in your farrier box.

“This is super fine,” he says. “It doesn’t feel like there’s any grit on it. This is the belt that’s used to polish all of your tools.”

Since the backing is polyester cloth, the belt is designed to be durable while enabling flexibility for the user to negotiate irregular profiles.

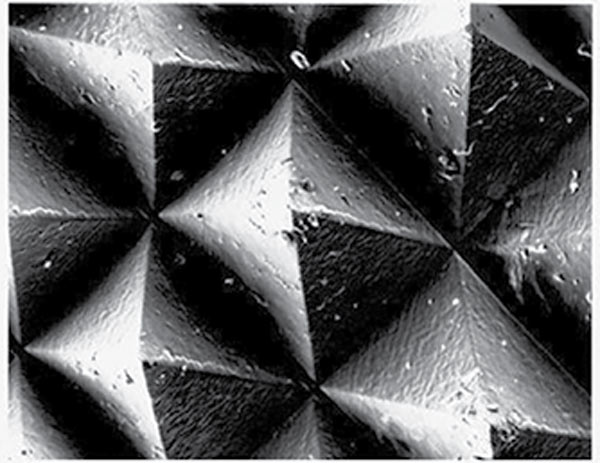

“These attributes make it a good match for flat or centerless finishing applications, which require a sturdy abrasive that is still sensitive to surface irregularities,” according to 3M. “A proprietary 3M technology, microreplication involves engineering and reproducing precisely sculpted microscopic shapes, with extreme uniformity, across a surface. In the case of abrasive mineral, that surface is a cloth or film backing.

“As these structures break down during use, new mineral is continually exposed. The uniform configuration and spacing of 3M Trizact abrasive minerals reduces the risk of uneven finishes and contributes to consistent and predictable performance from start to finish.”

The 3M Trizact aluminum oxide belt is used by many farrier tool manufacturers to polish their products. As the belt is used, the sculpted microscopic abrasive material (below) breaks off, creating new mineral to polish metal.

Understanding Grit

A 40-grit grinding belt might be among the most popular among farriers. After all, the majority of all grinding at the shoeing rig involves adding mechanics to the shoe. However, it’s not necessarily the best choice for other tasks.

“We think about 40-grit belts all the time because we grind shoes with them,” says Parrish, Fla., farrier Robbie Hunziker. “They hog all this material off. They’re made to do that. It’s not pretty looking. We think it is because we’re grinding shoes. If you were sharpening your knife with it, though, you’d ruin it. You’d run out of metal before you could remove the gouges from the blade.”

While a 40-grit belt is aggressive, that doesn’t mean it has more grinding material applied to the belt.

“There’s actually less pieces of sand per square inch, let’s say, on a 40-grit belt than there is on a 220,” explains the co-owner of Hurricane Forge Tools. “And, there are less on a piece of 220 than there are on a piece of 320. So, the finer the belt, the more pieces of grit that are on it.”

LEARN MORE

Watch a video in which Doug Workman explains how he uses a grinder with two expansion wheels for shoe modifications and fixing tools by visiting

americanfarriers.com/0417

You’ll also notice another difference with belts, Hunziker says.

“The finer the belt,” he says, “the hotter these things get quicker.”

Of course, heat is not an ally when sharpening a hoof knife.

“That’s the advantage of having grinders than most knife makers have,” Hunziker says. “They have variable speeds.

“We don’t have variable speeds while we’re on the job, though. So, water is your friend when you’re sharpening your knife. It’s your friend as long as the blade doesn’t get hot. Just keep dipping it. Once you get it hot, you’ll take the temper out of it. The blade will get scorched and it’s over.”

Understanding grit and the general colors of grinding belts can help you select the best choice for the task at hand.

Post a comment

Report Abusive Comment