From anvils to rasps and hammers to nippers, keeping your shoeing tools in tip-top order and knowing how to properly use them can save both time and money in your shoeing business.

One of the most important tools a farrier can have is safety glasses, says International Horseshoeing Hall of Fame member Gordon Haight of Eagle Point, Ore.

Haight knows firsthand the value of safety glasses. He lost an eye in an accident 21 years ago. He has been able to compensate and overcome this disability considerably, but tells others not to learn the hard way.

A pair of safety glasses can run $3 to $5. “Your eyes are worth a whole lot more than that,” Haight says.

“All it takes is just one spark from that grinder. Protection is extremely important.”

Hammering It Home

Having a good hammer is key in doing a good shoeing job, Haight says.

“The hammer should have good recoil off the anvil,” he says.

Haight maintains the round side of the hammer should be used for punching. “It will always drive the punch straight unlike the flat side of the hammer,” he says.

“It’ll drive it in quicker, easier, more efficiently and cleaner with the round side.”

When using the flat side of the hammer on punches, the hammer will have a tendency to flop the punch around if it is not hit perfectly. “That’s one mistake I see a lot of guys make,” Haight says.

“Your hammer should be balanced to a point that when you drop it, it stays in the position you dropped it at.”

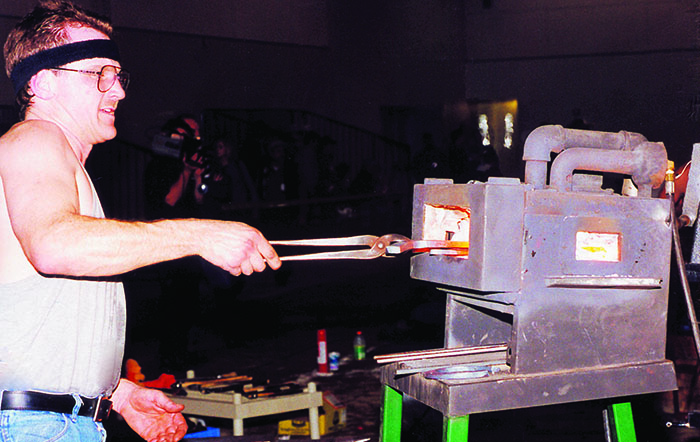

A GOOD FIT. The tongs you use should fit the material you’re using, especially while at the forge, like this farrier. If the tongs don’t fit properly it can be dangerous.

The hammer handle should be an ideal length that suits you and shouldn’t cause pain in your arms and shoulders. “Let the hammer do the work,” Haight says.

Keep your grip loose. Haight has seen farriers who are having difficulty with their elbows, shoulders and wrists after just 2 or 3 years on the job because of how they hold the hammer.

“They’re not using that hammer properly,” Haight says. “If the hammer is too light, they are trying to muscle it to do the job. If it is too heavy, they can’t have the control they need and they put too much of a death grip on the handle.

“I’ve known guys that have had to quit shoeing horses because they just didn’t have anything left after a while.” he says.

For hammer handles that get slick, Haight suggests wiping them with beeswax, paraffin, pine tar and other similar substances.

Analyzing Anvils

“Basically an anvil is nothing but a pattern maker,” Haight says. “The shape of the horn, the design and style of the anvil are there for you to make your shoes as efficiently as possible.”

“Find an anvil that’s the ideal weight, size and height for the kind of work you’re doing,” suggests Haight.

For instance, if you’re working with heavy iron or turning a lot of shoes, a heavier anvil might work best.

Over the years there have been many modifications and changes in the design and style of anvils. One modification Haight has on his anvil is a slot for punching.

“Make sure your modification doesn’t compromise or sacrifice the function of your anvil,” Haight warns.

Packed With A Punch

Haight prefers straight punches for his work. He suggests farriers rotate the shoe so they are square to the punch they are using. “You’d be amazed at how much you can actually improve your punching just by putting yourself in a position to where you’re square with the hole you’re punching,” he adds.

Haight suggests establishing a rhythm for pounding punches by noting how many hits it takes to come up with the hole you want. “After a period of time, you won’t even have to look at those holes,” he says.

To rework a punch, Haight suggests using a pair of tongs to hold the punch stable. Put the punch in the forge and heat to a temperature between 1,600 and 1,800 degrees Fahrenheit. Once it cools down to 1,200 to 1,300 degrees, do some light shaping of the punch to pack the molecular structure of the steel. This packing makes the steel tougher, stronger and harder.

Then allow the punch to slowly cool down.

Creasers Shouldn’t Flop

Some farriers complain that creases are coming out too wide in their shoes. “This is caused by letting the creasers flop over when they are hit, Haight says, adding, “You want to hold your creasers square.

“The area that’s being cut should be directly below the center of where you’re hitting. It should never be offsides. Make sure you’ve got a creaser that’s designed to be square and your creases will come out considerably cleaner,” he explains.

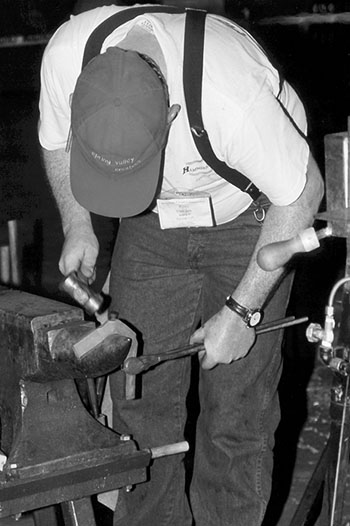

DON’T FLOP. Creasers shouldn’t flop to the side when they’re hit with a hammer. Be sure to hold your creasers square. The area you’re cutting should be directly below the center of where you’re hitting.

Forging Ahead

There isn’t a whole lot to do in keeping your forge in top order, says Haight.

Sometimes the liner needs to be replaced and that can be pretty costly. But what you’ll spend on extra propane if it isn’t replaced will more than pay for the replacement. After a while there will be a certain amount of carbon buildup which will affect the performance of the forge.

The orifices of the forge are fairly easy to get into and can be cleaned using welding tip cleaners. The tubes leading to the orifices need to be periodically blown out with a brush or air compressor.

If you have a double-burner gas forge, run both burners at the same time, suggests Haight. “Really it works best if you’re running the whole thing. You won’t consume more fuel. You’re compromising the design of the forge when you run just one burner,” he adds.

Hold On Tight

The tongs you use should fit the material you are using, Haight says. The shoe should stay in position and not rotate.

“If the tongs don’t fit properly it can be dangerous,” Haight says. He learned this the hard way once when a shoe flew off his tongs and his shirt caught fire.

Nip Problems In the Bud

Nail nippers are cheap enough that they can be replaced easily. There are nail nippers designed specifically for farrier use, but Haight says you can go to a local hardware store and buy carpenter nail nippers for less money and that will work as well.

MAINTAINING TOOLS. Choose an anvil that’s the ideal weight, size and height for the kind of shoeing work you do. Keep hammers and tongs in good working order. Your gas forge also needs a little maintenance once in a while.

Haight says the greatest farrier tool invention in the world are half-round nippers. “I can’t live without these anymore. They’re an invaluable tool.”

They should be kept well lubricated. They can be sharpened, but they should be rebuilt if there is a lot of wear.

Putting nippers in a shoeing box rather than throwing them on the ground will go a long way toward keeping them in good shape, Haight says.

Cleaning Rasps

When your rasps start loading up, use a wire brush to clean them. Haight suggests doing this between horses. A hoof pick and screwdrivers can also be used to help keep rasps clean.

Make sure your rasp doesn’t rust, Haight advises. He suggests spraying WD-40 on rasps if they are a little wet at the end of the day.

A Sharp Edge

“A knife is dangerous when it is dull. Don’t continue working with it,” says Haight. “The sharper the knife, the less pressure it takes and the easier it makes your job.”

Follow the contour of your knife when sharpening it. Haight uses a Diamond sharpener and then a buffer.

“It only take 2 seconds,” Haight says. “Don’t wait too long.”

Words Of Wisdom

Be organized and know where your tools are, says Haight. “Try to keep everything organized and very efficient. This saves a lot of time,” he says.

Post a comment

Report Abusive Comment