Farrier Takeaways

- No one shoe is going to be the best choice for all horses. The correct shoe for an individual horse depends on a variety of considerations.

- Work, intensity, duration, terrain and horse (WIDTH) offer parameters to guide shoe selection.

- Cross-section and ground surface features are the most important considerations for horseshoe selection. Front hind patterns, pre-made clips and factory modifications are secondary conveniences.

Horseshoe production has developed to a high level of quality and variety that’s unparalleled since the 1900s. The many companies that have emerged in the last 35 years, as well as the ease of manufacturing and importing shoes from all over the world, have enabled farriers to have unprecedented choices in our modern age.

Even with all the manufactured shoes available, hand-forged horseshoes have also risen to high levels of quality and popularity, due to contests, clinics and the willingness of farriers to pursue this skill. The growth of the farrier industry has led to many companies competing for market share. Often, there are many good copies of a particular horseshoe type or style, as well as many specialty shoes aimed at the various niche markets. The only problem with all this is at times, farriers may have a difficult time deciding which shoe is the best option for the horses that they are working on. The finest manufactured shoe or the prettiest hand-forged shoe will not be much help to the horse wearing it, if it is the wrong type for the horse’s work.

Because of the many shoe choices available, I’m often asked by my students how to decide which shoe to select for a particular horse. With so many options, there needs to be a logical way to choose. I created the WIDTH Protocol, (American Farriers Journal, May/June 2013) as an objective method of determining whether a particular horse needs shoes or can be barefoot, but it is also a good method to identify the type of horseshoe that would best suit an individual horse. This protocol is applicable for all horses and shoes, manufactured or hand-forged, nailed, or glued.

Using the WIDTH protocol takes brand or personal bias out of the process. Over the course of my career, I have used many different shoe styles according to the needs of the horses. Basic generic shoes can be used the way they are or modified. Too often the same shoe types, unmodified, are used for all horses. I would rather fine tune my shoeing with shoes that are selected for their properties beyond my modifying and fitting.

Briefly, the acronym WIDTH stands for work, intensity, duration, terrain and horse. These five parameters define all aspects of an individual horse’s needs for footwear. Let us review the WIDTH protocol as it applies to horseshoes.

- Work. All the work that horses do is not the same. Think about the way people wear shoes. You could inappropriately wear your steel toe work boots to a wedding and get away with that, but if you wore the same boots to run a marathon, you would likely suffer and not be competitive. The shoes that work best to run a marathon would likely cause a ligament strain playing basketball. Therefore, “work” is about what a horse usually does or what footwear that horse needs to be competitive or safe.

- Intensity. Transmitting power to the ground for propulsion is represented in the word “intensity.” Low intensity is walking and jogging, whereas high intensity is collected gaits and speed. A quiet trail ride is low intensity. A horse race, polo game, dressage test, barrel race, calf roping, etc., are all high intensity. A pulling/logging horse may not move very fast but still needs to transmit large amounts of power to the ground. So here, the consideration is how well does a shoe interface with the ground to apply the horse’s power.

- Duration. This refers to the durability of the horseshoe, how long the shoe needs to last, or the length of the shoeing interval. Light aluminum racing shoes do not need durability beyond several weeks, whereas a horse competing in 100-mile endurance races needs exceptional durability.

- Terrain. This can the biggest variable and is affected by changing moisture/weather conditions. Some horses have the luxury of working in constant environments, while others need to be prepared for whatever comes their way. Dressage and reining horses work in predictable quality footing while 3-day eventers travel from venue to venue and are at the mercy of changing weather conditions.

- Horse. Different breeds and individuals within a breed have different needs. The health, age, soundness and husbandry will influence horseshoe requirements. For instance, most Thoroughbreds usually have thin walls and soles but occasionally some do not. They also lend themselves wellto be trained for many different uses. Therefore, each horse may have different horseshoe needs than others of the same breed or sport.

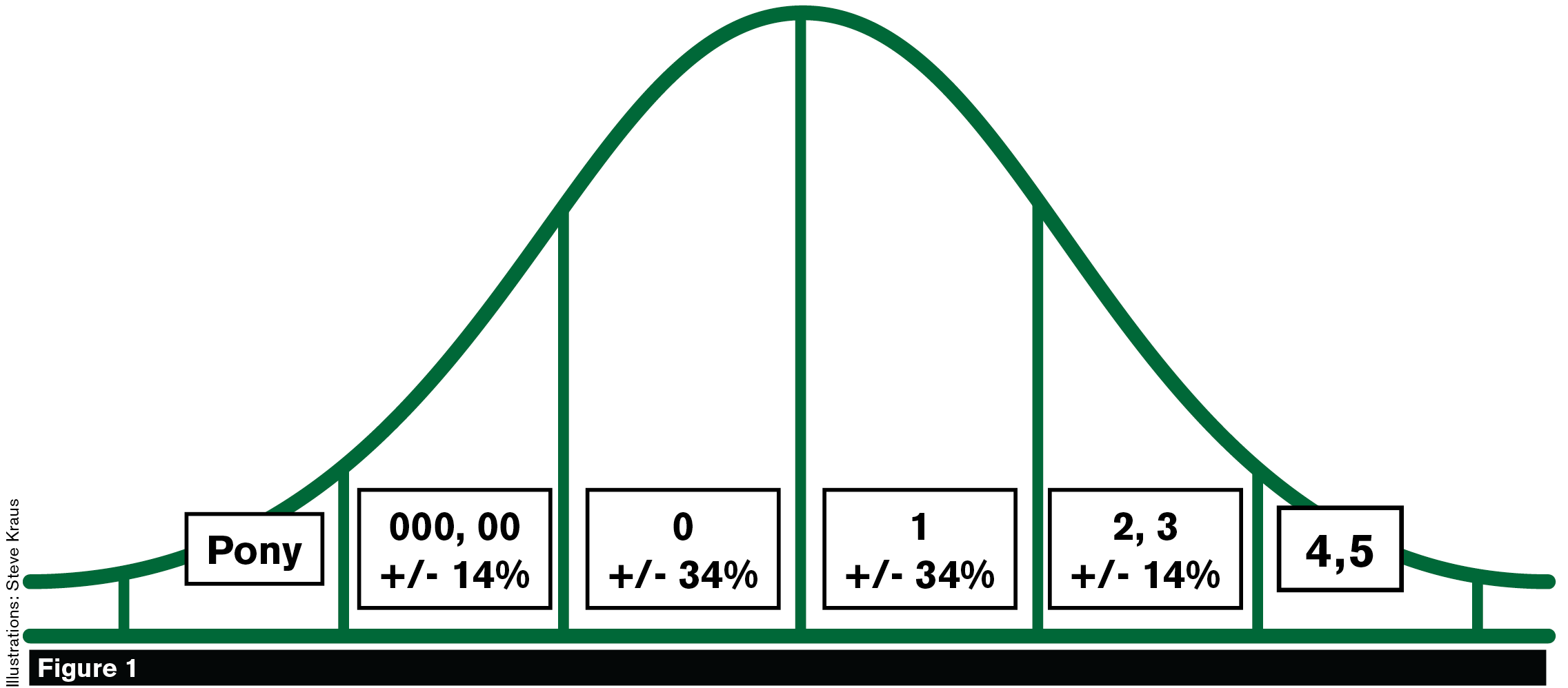

Before we get into specifics, let us define some terms about horseshoes. “Cross-section” refers to the thickness/width of the stock dimension of any shoe — hand-forged or manufactured. In current times, there is an average horse size for most horses in use. Think of the “bell curve” in which 80% of the shod horses will have feet that will fit shoes in only a few manufactured sizes (Figure 1). On the left side of the “bell curve,” are the fewer smaller footed horses and the right side will have the fewer larger footed horses. Manufactured horseshoe sales reflect this.

A “bell curve” in which 80% of the shod horses will have feet that will fit shoes in only a few manufactured sizes illustrates the “average” horseshoe size. On the left side of the “bell curve,” are the fewer smaller footed horses and the right side will have the fewer larger footed horses.

Even though there is a small range of popular sizes, there is also some variation of ground surface features and cross-section size for those shoes. Being that a large number of horses in the middle range have a hoof wall that is plus or minus 3/8 inches, a standard width shoe doubles that width for these horses and would be 3/4 inches. A shoe width narrower than this is known as a light shoe (Lite). A shoe that has a wider width is a wide web shoe (Extra, Plus, etc.). With this reasoning, a standard shoe web width may work as a wide web shoe for a smaller foot and a wide web shoe is usually a standard shoe for the larger hooved horses. A standard web width shoe would function as a light shoe for the larger feet.

The previous paragraph is referring to the way shoes for the American market are described. Most European shoes may have trademarked names; however, the cross-section sizing is shown in millimeters. For instance, an 8-by-19 millimeter (SX8) is similar to a standard Plain 5/16-by-3/4-inch shoe. A 7-by-17 millimeter is similar to a Lite shoe. A 10-by-24 is similar to a wide web shoe in large sizes for bigger horses.

Another variation is ground surface. Many hand-forged shoes are referred to as plain-stamped, meaning no real change of the ground surface. Along with this, most manufactured shoes and some hand-forged shoes are creased or fullered, which provides slightly more traction than a flat shoe. The creases also provide a groove for the nail heads.

Another ground surface feature for more traction, manufacturers produce “rim” style shoes, which continues the fullering around the toe to the heels. Concave steel is similar, which produces a continuous groove and a cut out inside edge, which lightens up the cross-section and aids penetration into the ground.

As the horseshoe market has become more competitive, manufacturers have produced new styles with modifications that farriers formerly had to produce by forging or grinding. Reduction of leverage with factory rolled or blunt toes, or half rounds (rollers), make the farrier’s job easier. Pre-made bar shoes and asymmetrical shoes for therapeutic purposes are all available, as well as many different glue-on shoes. The convenience of specialty shoes comes with increased cost and adding additional inventory.

Now that we know that there is a shoe for almost any foot, work or condition, how do we decide the best options? Here is where the WIDTH protocol comes in. Each WIDTH parameter will define the limiting factor to consider.

Work

Work is the horse’s job. That job may be training hard miles for speed and endurance or that job may be moving properly in the show ring. Shoes that are helpful for the horse’s job should be considered instead of a generic horseshoe. Horses in specific work need shoes that enhance that horse’s ability to perform. For instance, a hunter in the show ring needs lighter shoes to enhance movement, but a field hunter needs shoes that provide durability and safety while galloping cross country.

Intensity

Most of what a horse does is propulsion, or applying power to the ground. Toe grabs on draft horseshoes or aluminum racing plates allow the delivery of intense power. Without a way to interface with the ground, power is wasted. Rim and concave shoes or added traction devices provide more grip allowing this delivery without slippage.

Duration

Length of shoeing interval, competition schedule and distance traveled make up the durability component. How long does the shoe need to last? If a shoe wears out before the end of the desired shoeing cycle, the cross-section is either too thin or the shoe needs a wear prevention measure such as Borium or Drill Tek.

Terrain

Weather and soil types interact with each other. Hard abrasive ground limits the durability of shoes. Horses working on pavement need different shoes than horses working in show rings. Slippery surfaces such as ice, pavement and mud need traction. Horses competing in reining and dressage need a lack of traction or flotation. Needed slip for joint protection should be balanced with traction for safety, for the horse, as well as the rider.

Horse

Within breeds or uses of horses, there is a certain amount of uniformity similar to the standard distribution curve in Figure 1.There is a large group of similar horses in the middle of the group with outliers on the edges. These outliers will likely need different shoes or cross-sections than the rest of the group, even though they may be doing the same activity. Individual health, injury, management and use concerns will also come into play for an individual’s shoe selection.

A horse’s needs may only be protection or a different shoe might be needed to enhance performance. The question is always, which shoe helps the horse do its job in the best, safest way?

When we look in farriery textbooks describing horseshoes, we see pictures of specific shoes: Arabian shoes, hunter shoes, polo shoes, race horseshoes, etc. All these different shoes have specific attributes that help horses perform or be more competitive than being shod with a generic shoe. These specialty shoes have characteristics that enhance performance.

However, it is also important to not be hung up on specific names placed on shoes by manufacturers. For instance, an Arabian style toe-weight shoe is used to enhance movement in the show ring, but is not needed for horses that are not showing.

The popular “Eventer” shoe is used for many different Western performance horses, as well as 3-day event horses.

The most important considerations for horseshoe selection are cross-section and ground surface features. Conveniences, such as front-hind patterns, pre-made clips and factory modifications are secondary.

Although most farriers are adept at modifying generic factory-made shoes, taking advantage of the variety in today’s market should reduce the amount of human energy used to shoe a horse.

LEARN MORE

Gain more insight on choosing the proper shoe by:

- Reading “The WIDTH Protocol” in which Steve Kraus offers the objective guidelines to determining whether a horse should be shod or go barefoot.

- Reading “Matching the Shoe to the Job” in which farriers offer their perspective on shoe selection factors.

- Watching “Shoe Size Selection” in which Florida farrier Fabio Gnoatto explains his shoeing preferences.

Access this content by visiting americanfarriers.com/0121

Post a comment

Report Abusive Comment